- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/415V/440V

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Product name:

-

Automatic molding machine

-

Application:

-

Foundry Industry

-

Usage:

-

Foundry Castings Production

-

Type:

-

Horizontal

-

Name:

-

foundry moulding machine

-

Technology:

-

Clay Sand Technology

-

Material:

-

Clay sand

-

Function:

-

sand molding

-

Capacity:

-

40-60 moulds/hour

-

Color:

-

Customized Color

-

Certification:

-

ISO/CE

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

Sand molding machine

-

Brand Name:

-

Qingdao ANTAI

-

Voltage:

-

380V/415V/440V

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Product name:

-

Automatic molding machine

-

Application:

-

Foundry Industry

-

Usage:

-

Foundry Castings Production

-

Type:

-

Horizontal

-

Name:

-

foundry moulding machine

-

Technology:

-

Clay Sand Technology

-

Material:

-

Clay sand

-

Function:

-

sand molding

-

Capacity:

-

40-60 moulds/hour

-

Color:

-

Customized Color

-

Certification:

-

ISO/CE

Products Description

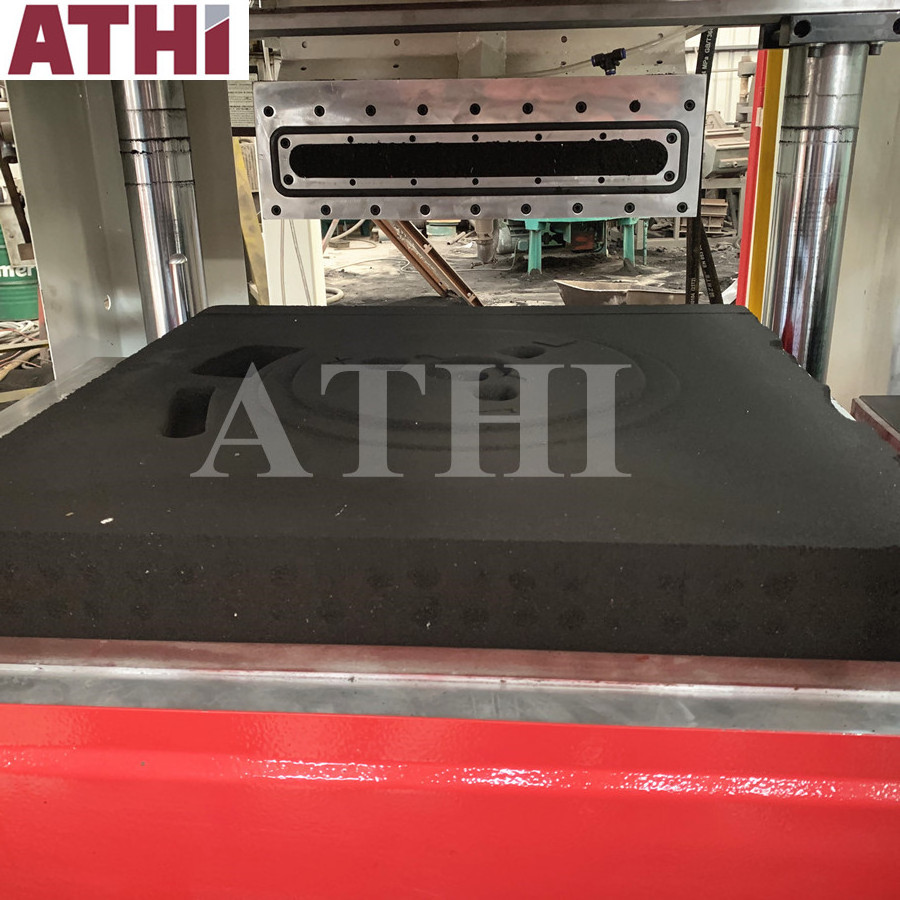

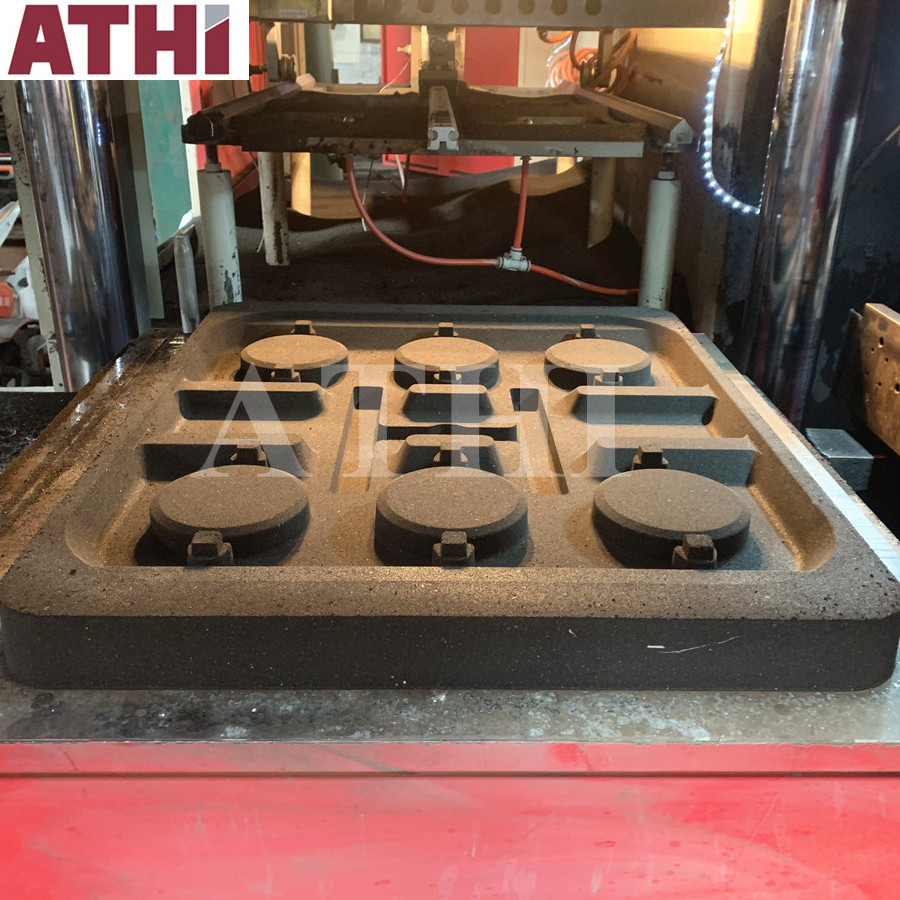

The molding machine adopts double-sided template, pneumatic sand feeding.Uniform hardness, flask closing high precision and adjustable sand thickness;easy replacement of template.

The hydraulic oil temperature control ensures the best running state of the equipment.This machine is easy to operate, double safety protection, visual sand type situation, operating procedure is humanized.

Improve productivity effectively.

The hydraulic oil temperature control ensures the best running state of the equipment.This machine is easy to operate, double safety protection, visual sand type situation, operating procedure is humanized.

Improve productivity effectively.

Technical parameters

Main Parts

We choose popluar electric and hydraulic parts at home and broad, CHNT, SIEMENS, SCHINEIDER, OMRON, MITSUBISHI,ABB SEW, etc. Custom brands are also accepted.

Advantage:

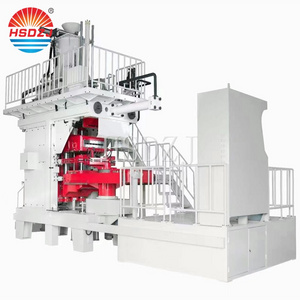

1. Improve the production efficiency,save the human resource. 90mold/h capacity.

Horizontal parting flaskless automatic molding machine.

Equivalent to squeeze molding machine 5 sets + 5 worker.

2. Implement quality improvement and stability

Reduce the parting, Improve parting accuracy

With high rigidity guide rod support

Through the support of four high rigid guide rods to achieve high accuracy parting, mould assembling.

The maximum 0.9MPa of the extrusion pressure to improve the quality of the mold.

3.Reduce operating costs, save energy, improve the environment

Reduce the use of sand

Reduce the flying sand, sand scattered

Box up and down in closed state ,molding at the same time

Feature :

1.Horizontal parting, convenient lower core.

2.Mould height adjustable, save sand.

3.Intelligent control, no need of professional workers, the operation is simple and quick.

4.Can be composed of production lines,also can be stand-alone production.

5.Safety light switch, ensure absolute safety under the core process.

6.High efficiency and stability, 24 hours to run, to provide sustained productivity.

7.Can do complex castings.

8.Touch screen, parameter modification, immediately visible.

9.Hydraulic power, stable operation, high degree of compaction.

10.The sand box is provided with exhaust holes.

11.Angle of the sand shooting valve can be adjusted.

12.Hydraulic extrusion molding, the operating environment is more quiet.

Horizontal parting flaskless automatic molding machine.

Equivalent to squeeze molding machine 5 sets + 5 worker.

2. Implement quality improvement and stability

Reduce the parting, Improve parting accuracy

With high rigidity guide rod support

Through the support of four high rigid guide rods to achieve high accuracy parting, mould assembling.

The maximum 0.9MPa of the extrusion pressure to improve the quality of the mold.

3.Reduce operating costs, save energy, improve the environment

Reduce the use of sand

Reduce the flying sand, sand scattered

Box up and down in closed state ,molding at the same time

Feature :

1.Horizontal parting, convenient lower core.

2.Mould height adjustable, save sand.

3.Intelligent control, no need of professional workers, the operation is simple and quick.

4.Can be composed of production lines,also can be stand-alone production.

5.Safety light switch, ensure absolute safety under the core process.

6.High efficiency and stability, 24 hours to run, to provide sustained productivity.

7.Can do complex castings.

8.Touch screen, parameter modification, immediately visible.

9.Hydraulic power, stable operation, high degree of compaction.

10.The sand box is provided with exhaust holes.

11.Angle of the sand shooting valve can be adjusted.

12.Hydraulic extrusion molding, the operating environment is more quiet.

Production & Castings

Packing&Delivery

1.Equipment painting completed before shipment, With Stretch film to avoid rub off the surface paint, It can used wooden cases packaging according to users requirements.(Key parts such as electric cabinet with shockproof packaging material and then packed in wooden cases. )

2. We have 15 experienced engineers, With 108 skilled workers insure good quality of our machines and prompt delivery.

3.Meanwhile our company has a long-term cooperation with ACL, CSCL, CCNI, CNC, COSCO etc insure the goods to the port on time.

2. We have 15 experienced engineers, With 108 skilled workers insure good quality of our machines and prompt delivery.

3.Meanwhile our company has a long-term cooperation with ACL, CSCL, CCNI, CNC, COSCO etc insure the goods to the port on time.

Hot Searches