- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MEIZLON

-

Voltage:

-

220V/380V/415V

-

Dimension(L*W*H):

-

5800mm*1200mm*2100mm

-

Power (kW):

-

160

-

Weight:

-

4000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Screw structure:

-

modular screw structure

-

Screw:

-

segment

-

Product Type:

-

twin screw extruder

-

Output:

-

150-200kg/h

-

Control:

-

PLC control systems available

-

Screw diameter:

-

51.4mm

-

Inverter:

-

ABB

-

Motor:

-

Siemens

-

Gearbox:

-

High torque gearbox

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

44/1

-

Screw diameter (mm):

-

51.2

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MEIZLON

-

Voltage:

-

220V/380V/415V

-

Dimension(L*W*H):

-

5800mm*1200mm*2100mm

-

Power (kW):

-

160

-

Weight:

-

4000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Screw structure:

-

modular screw structure

-

Screw:

-

segment

-

Product Type:

-

twin screw extruder

-

Output:

-

150-200kg/h

-

Control:

-

PLC control systems available

-

Screw diameter:

-

51.4mm

-

Inverter:

-

ABB

-

Motor:

-

Siemens

-

Gearbox:

-

High torque gearbox

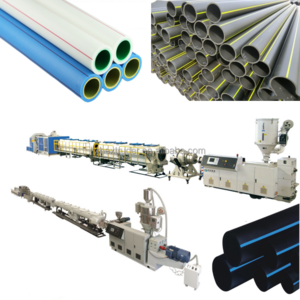

PET master batch twin screw extruder machine

|

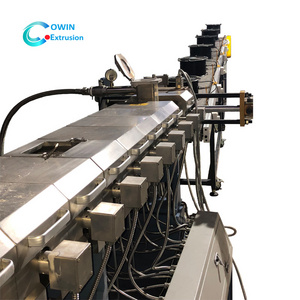

>>Gearbox

Reduction transmission: High torque gearbox

|

|

> >Screw Screw Kneading block built on modular principle allows various L/D ratio of screw easily be changed to suit different material. Screw component made of high speed & wear-resisting steel. |

|

> >Barrel By means of the replaceable screw barrel sections, the processing sections is devided into individual zones. The barrels are heated electrically. In addition, the barrels are provided with longitudinal bores for cooling with water. Uniform temperature distribution, namely on the circumference of the eightshaped barrel bore, is achieved by a reverse forceflow temperature control circuit. Connections of pipes for temperature control are in groove-tongue design to balance alternating thermal stress and avoid leakage. |

|

Model

Parameter |

Screw Diameter

(mm) |

Groove depth

(mm) |

L/D |

Motor power

(KW) |

Rotating speed

(rpm/min) |

Output

(kg/h) |

| MT-20 | 21.7 | 3.85 | 28/60 | 4 | 600 | 5-15 |

| MT-26 | 25 | 4.1 | 28/60 | 5.5-10 | 600 | 10-40 |

| MTG-36 | 35.6 | 6 | 28-60 | 15-55 | 600 | 15-120 |

| MT-40 | 41 | 7 | 28-60 | 30-37 | 500/600 | 50-150 |

| MTG-52 | 51.4 | 9 | 28-60 | 55-160 | 500/600/900 | 150-350 |

| MT-60 | 60 | 10 | 28-60 | 45-75 | 400/500/600 | 100-300 |

| MT-65 | 62.4 | 11 | 28-60 | 55-90 | 400/500/600 | 150-400 |

| MT-75 | 71 | 12 | 28-60 | 110-250 | 400/500/600 | 250-800 |

| MT-95 | 92 | 16.3 | 28-60 | 200-315 | 400/500/600 | 650-1500 |

| MT-135 | 133 | 23.5 | 28-48 | 600 | 300/400 | 1500-3000 |

Application for plastic