- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Clear

-

Voltage:

-

220V or 380v or 415v or Customized

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized as customer's maximum workpiece

-

Weight (KG):

-

8000

-

Pretreatment:

-

Chemical pre-treatment or sand or shot blasting machine

-

Recycle System::

-

cyclone and Filter Cartridge box

-

Material of powder coating booth::

-

Galvanized Cold Sheet/PP Panel/Stainless steel sheet

-

Control System::

-

PLC+Touch Screen Automatic

-

Water curing off oven::

-

For baking water

-

The heating fuel of oven::

-

Gas or Diesel or LPG or Electric

-

Evironmental::

-

Protective

-

Powder Recovery Capacity::

-

98%

-

After Warranty Service:

-

Spare parts

Quick Details

-

Machine Type:

-

powder coating system, Spray Booths, Painting Equipment, Plc Controller Programmable Logic Controller, Pre-treatment Equipment, Conveying Equipment, Drying Oven, Curing oven, Coating Equipment, Anodized Equipment, Sandblasting Machine, Other

-

Marketing Type:

-

New Product

-

Warranty of core components:

-

2 Year

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Clear

-

Voltage:

-

220V or 380v or 415v or Customized

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized as customer's maximum workpiece

-

Weight (KG):

-

8000

-

Pretreatment:

-

Chemical pre-treatment or sand or shot blasting machine

-

Recycle System::

-

cyclone and Filter Cartridge box

-

Material of powder coating booth::

-

Galvanized Cold Sheet/PP Panel/Stainless steel sheet

-

Control System::

-

PLC+Touch Screen Automatic

-

Water curing off oven::

-

For baking water

-

The heating fuel of oven::

-

Gas or Diesel or LPG or Electric

-

Evironmental::

-

Protective

-

Powder Recovery Capacity::

-

98%

-

After Warranty Service:

-

Spare parts

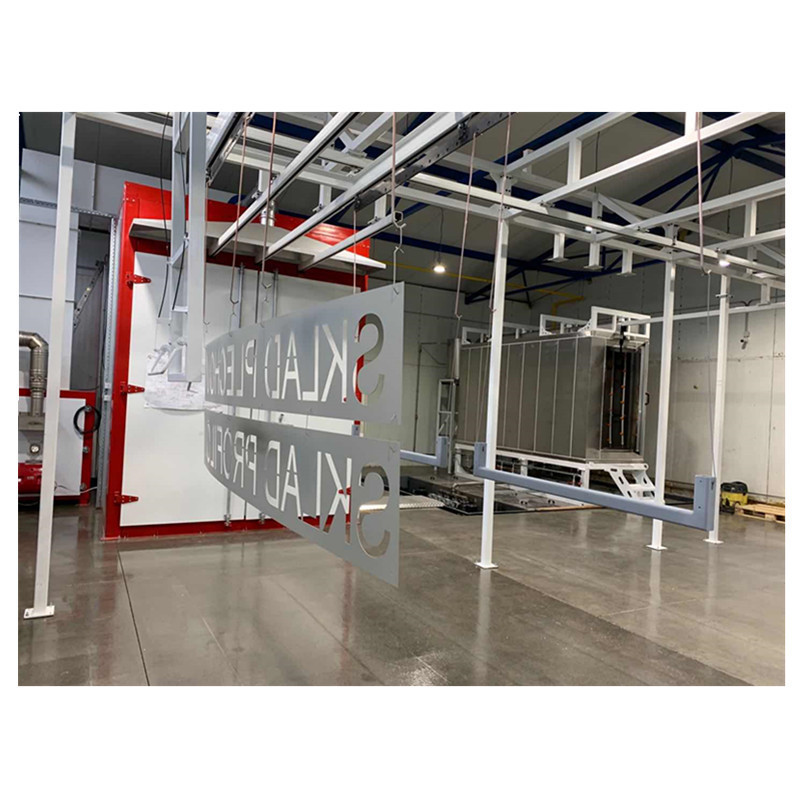

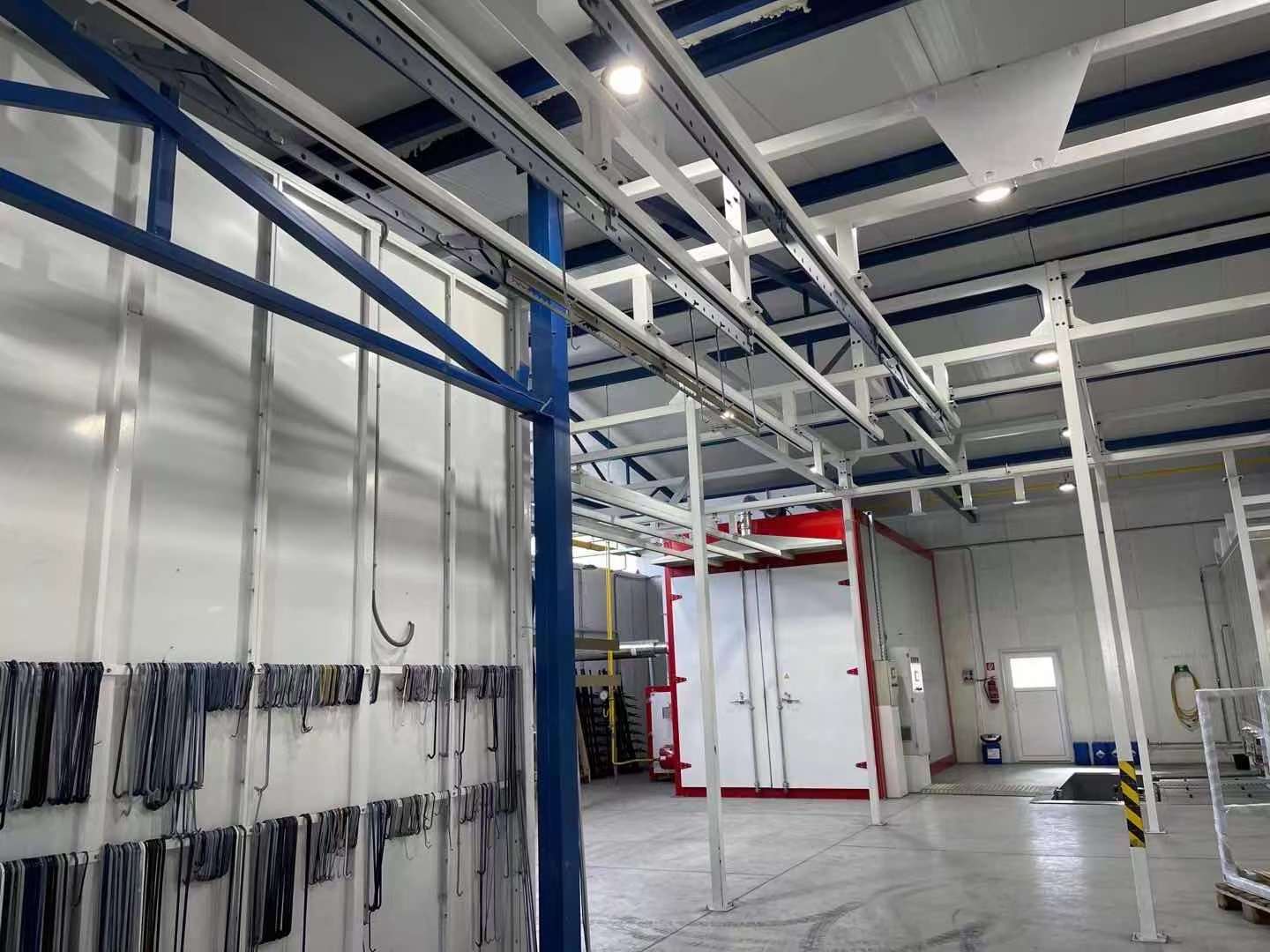

Manual Horizontal Powder Coating Conveyor Line

This powder coating line is designed for continuous production based on manual operation. It is ideal for big or complex workparts that requires precise coating jobs, as well as batch production of small parts.

This manual coating line includes overhead conveyor system, pass thru powder coating booth and curing ovens, manual powder painting machines. The horizontal pull conveyor system allows moving heavy objects with less efforts.

Customer Case

These manual powder coating line are designed and manufactured by Clear, built in customer's Factory, they do powder coatin

application for aluminum profiles and metal frames, fence, etc.

application for aluminum profiles and metal frames, fence, etc.

Product Description

Clear Pass Thru Powder Spray Booth

This tunnel powder coating booth has 2 working station allows parts recieving coating from both side, parts enter the booth from one entrance and exit from the other through conveyors, continuous coating increases efficiency and ensures application quality.

|

Outside Size

|

4500x3000x2690mm(LXWXH)

|

|

Inner size

|

4400x2900x2600mm(LXWXH)

|

|

Wall panel

|

2mm thick cold rolled steel sheet with powder coating

|

|

Air Circulation System

|

2 sets of 5.5kw 4-72-5A outlay motor fan. Each fan air flow capacity:7000m³/h

Pressure is 2000Pa, speed is 2900r/min |

|

Powder recycling system

|

Filter system is filter cartridge box,2*4 pcs on each side,total 8pcs, each filter size: 324*900mm, with 8pcs pulse shaking

device. Air compressor pressure:0.6-0.8MPa,valve pressure:0.6Mpa. Finial powder recycling rate is 94% |

|

Sliding door

|

Two sets of sliding doors for closing the booth after the products go into the booth to avoid powder overflow,size:

2100*2200mm(W*H) |

|

Lighting System

|

Ceiling Light: 2*4 units 18w LED lights

|

|

Total power

|

11kw

|

Features

1. The recovery module combines high-precision filters made of 100% polyester that maximize separating efficiency

2. Pulse jet device provides interval filters cleaning, effectively eliminates powder accumulation and prolongs filters' useful

life.

3. Full parameters and functions can be handled on the PLC panel, such turning on / off fan, setting pulse-jetting time and

interval, light on/off, emergency stop etc.

4. The booth body is made of powder-coated steel plate constructed for rust resistance, durability and ease of cleaning.

2. Pulse jet device provides interval filters cleaning, effectively eliminates powder accumulation and prolongs filters' useful

life.

3. Full parameters and functions can be handled on the PLC panel, such turning on / off fan, setting pulse-jetting time and

interval, light on/off, emergency stop etc.

4. The booth body is made of powder-coated steel plate constructed for rust resistance, durability and ease of cleaning.

Clear Conveyor Powder Coating Oven

This powder coating oven can be heated by electric, gas or diesel as required. A circulation fan cycles hot air uniformly and keeps even temperature in the chamber. Our powder coating ovens features environmental friendly, reducing operating cost and curing more parts everyday.

Features

1. Using PLC system to control all heating process, accurate and conveninet.

2. Riello burner fully burns fuels (gas or diesel), quickly reach to required temperature.

3. Circulation fans causes uniform temperature in the entire chamber that results in quality cured finishes.

4. 100 mm thickness rockwool board always keeps the chamber with minimum heat loss.

5. We can custom powder coating ovens with required sizes, such as 6m, 7m, 8m, or more..

2. Riello burner fully burns fuels (gas or diesel), quickly reach to required temperature.

3. Circulation fans causes uniform temperature in the entire chamber that results in quality cured finishes.

4. 100 mm thickness rockwool board always keeps the chamber with minimum heat loss.

5. We can custom powder coating ovens with required sizes, such as 6m, 7m, 8m, or more..

Filter catridge

high efficiency filters for filter the powder,1-3um filtration efficiency,each filter size is 325*900mm

C-type conveyor

C-type galvanized steel track,for moving the products forward from loading place to unloading place,pulley inside the track single

point loading capacity is 200kg,

point loading capacity is 200kg,

Manual powder coating gun ,

Machine

20 years old powder coating gun factory, good performance,different models for choice,with durable quality and detail manual.

manual powder coating gun is developed with latest technology suitable for any parts any powders. Our powder coating

machines increase your production efficiency with great material savings.

The advanced DVC technology allows you to precisely control crucial paramters such as high voltage, spraying current and powder

outpur, achieving perfect and repeatable coating results.

There are 3 pre-set programs for high-grade spraying operations, including "Flat-parts coating," "Complicated parts coating," and

"Re-coating Workpiece." Advanced users can create and store 20 application programs, optimized for their parts and powder

machines increase your production efficiency with great material savings.

The advanced DVC technology allows you to precisely control crucial paramters such as high voltage, spraying current and powder

outpur, achieving perfect and repeatable coating results.

There are 3 pre-set programs for high-grade spraying operations, including "Flat-parts coating," "Complicated parts coating," and

"Re-coating Workpiece." Advanced users can create and store 20 application programs, optimized for their parts and powder

Detailed Images

Manual powder coating booth

Natural gas powder curing oven

Related Products

Packing & Delivery

After Sales Service

Free parts within 1 year warranty

Life long technical support and after sale service

Company Introduction

We have 3 workshops,each one is more than 2500 square meter ,we have aser cutting machine,shearing machine,bending

machine,punching machine,drilling machine,welding machine and painting booth in our factory.

We have 60 production workers,18 installation workers,10 engineers for oversea installation service and 16 technician for project

designing. Our office is 2000 square meter,we have international trade department,technology department,

production department,financial department,purchasing department and so on,total 52 office stuff.

machine,punching machine,drilling machine,welding machine and painting booth in our factory.

We have 60 production workers,18 installation workers,10 engineers for oversea installation service and 16 technician for project

designing. Our office is 2000 square meter,we have international trade department,technology department,

production department,financial department,purchasing department and so on,total 52 office stuff.

Our Services & Strength

oversea installation team and aftersale service

professional design team and production team

Why Choose Us

Exquisite and meticulous

We always adheres to the principle of quality first and customers first, and sincerely cooperates with domestic and foreign

customers to create brilliant business opportunities.

customers to create brilliant business opportunities.

Keep improving, with the concept and policy of sustainable operation, small profits but quick turnover, guarantee quality, and continuously provide customers with quality products.

FAQ

Q1

: What product can I customize from you?

A1: Various styles of powder coating and spraying production lines, industrial spray booths, environmentally friendly and

energy-saving spray booths, high-temperature rooms, through-type spraying, dry (water curtain) spraying chambers, electric hot air drying ovens, drying ovens and drying tunnels, hanging conveying equipment, Painting equipment such as furniture baking room.

A1: Various styles of powder coating and spraying production lines, industrial spray booths, environmentally friendly and

energy-saving spray booths, high-temperature rooms, through-type spraying, dry (water curtain) spraying chambers, electric hot air drying ovens, drying ovens and drying tunnels, hanging conveying equipment, Painting equipment such as furniture baking room.

Q2: What types coating line could you make?

A2: Automatic Powder Coating Line For Column,Powder Coating Line With Fast Color Change System,Automatic Powder Coating Line For Control Box,Powder Coating Line For Springs.

A2: Automatic Powder Coating Line For Column,Powder Coating Line With Fast Color Change System,Automatic Powder Coating Line For Control Box,Powder Coating Line For Springs.

Q3: Installation?

Deliver with detailed specification of installation and operation

Q4: Payment terms?

T/T,30% for deposit and the balance 70% before loading into container

Q5: More products models?

Products showcase on Alibaba: clear.en.alibaba.com

Official website: www.clear88.com

WhatsApp/ Facebook/ Cell phone/ WeChat/ Mobile : 0086-13668659906

Deliver with detailed specification of installation and operation

Q4: Payment terms?

T/T,30% for deposit and the balance 70% before loading into container

Q5: More products models?

Products showcase on Alibaba: clear.en.alibaba.com

Official website: www.clear88.com

WhatsApp/ Facebook/ Cell phone/ WeChat/ Mobile : 0086-13668659906

Email: goodclear04(at)clear88.com

Contact: Nina Wang

Contact: Nina Wang

Hot Searches