- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Qie

-

Voltage:

-

220V/380V/440V

-

Weight:

-

20000 KG

-

Marketing Type:

-

New Product 2023

-

Product name:

-

cooking oil production machine line

-

Raw material:

-

soybean, peanut, sesame, rice bran, etc.

-

Keyword 1:

-

soybean oil extraction machine

-

Keyword 2:

-

soybean oil production line

-

Factory visit:

-

welcome

-

Advantage:

-

Energy Saving Low Residual

-

Certification:

-

CE/ISO9001

-

MOQ:

-

1 Set

-

Color:

-

Customizable Color

-

Capacity:

-

1TPD-1000TPD

Quick Details

-

Max Capacity:

-

1000tpd

-

Production Capacity:

-

98%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Qie

-

Voltage:

-

220V/380V/440V

-

Weight:

-

20000 KG

-

Marketing Type:

-

New Product 2023

-

Product name:

-

cooking oil production machine line

-

Raw material:

-

soybean, peanut, sesame, rice bran, etc.

-

Keyword 1:

-

soybean oil extraction machine

-

Keyword 2:

-

soybean oil production line

-

Factory visit:

-

welcome

-

Advantage:

-

Energy Saving Low Residual

-

Certification:

-

CE/ISO9001

-

MOQ:

-

1 Set

-

Color:

-

Customizable Color

-

Capacity:

-

1TPD-1000TPD

Product Description

15 ton cooking oil making machine sunflower/soybean oil extraction/refinery machine production line

Complete soybean oil production line including

raw material pretreatment, oil pressing and oil refining.

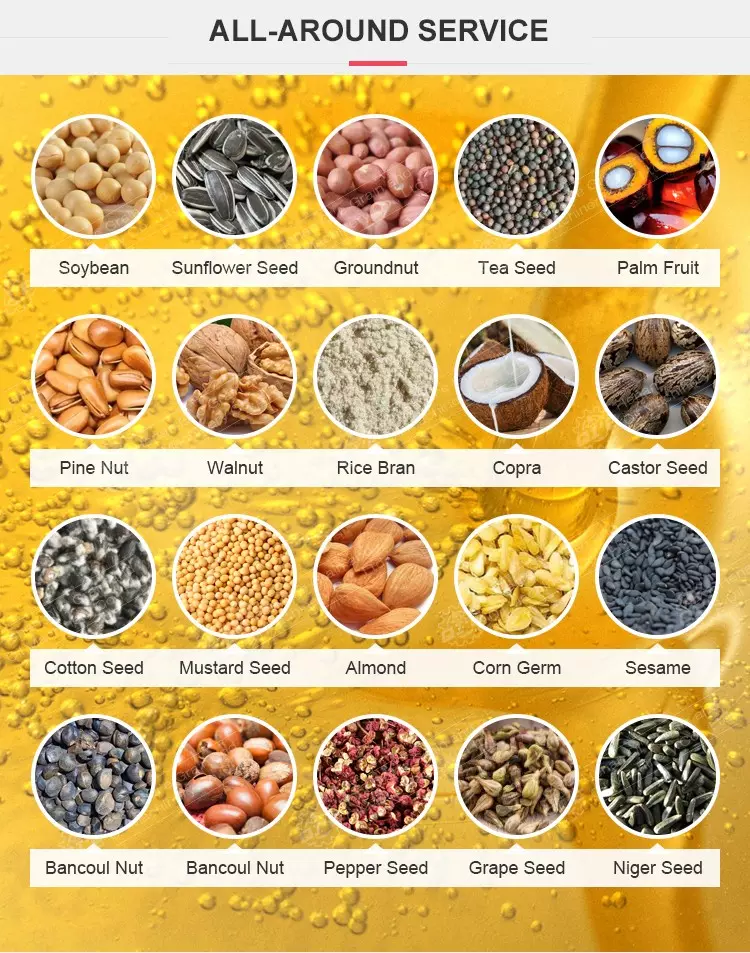

Our company have different machine suitable for all kinds of oil seeds,

eg: sunflower seed, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Product parameter of

15 ton cooking oil making machine sunflower/soybean oil extraction/refinery machine production line

|

Usage

|

Soybean oil production line

|

|

Type

|

Cold & Hot Pressing Machine

|

|

Automatic Grade

|

Automatic

|

|

Place of Origin

|

China

|

|

Voltage

|

220V/380V/440V

|

|

Oil type

|

Soybean Oil

|

|

Max Capacity

|

3000tpd

|

|

Product name

|

cooking oil production machine line soybean/sunflower/peanut oil press extraction machine

|

|

Raw material

|

Peanut, soybean, sunflower, sesame, mustard, ect.

|

|

Factory visit

|

welcome

|

Our company have different machine suitable for all kinds of oil seeds

, eg: sunflower seed, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Section 1: pre-treatment process of

soybean/sunflower oil extraction/refinery machine line

:

Cleaning & Weighing - Cracking & Dehulling - Flaking - Cooking - Pressing - Oil Residue Separation - Cooling

Cleaning & Weighing - Cracking & Dehulling - Flaking - Cooking - Pressing - Oil Residue Separation - Cooling

Benefits of oil pre-treatment :

1. Create a good production environment;

2. Minimize the total oil loss, increase oil yield and output, also improve the quality of oil and cake meal;

3. Comprehensively utilize impurities and offal;

4. Perfectly, match extraction production line, designing different production processes according to different oil seeds.

Section 2 : Oil pressing of

soybean/sunflower oil extraction/refinery machine line

:

Section 3: Oil refining of

soybean/sunflower oil extraction/refinery machine line

:

crude oil - degumming & dephosphorization - deacidification - drying - decolorization - deodorization - defatting - dewaxing - finished oil.

Oil refining can remove mechanical impurities, solute fat impurities, pigments, moisture and other impurities in the oil, and then to produce pure high-quality edible oil.

Section 3: Oil solvent extraction of

soybean/sunflower oil extraction/refinery machine line

:

1. Solvent Extraction

Oilseed flakes are conveyed to the extractor, then extracted by miscella with different concentration gradients and fresh solvent. The miscella will be pumped to the evaporation system and the spent meal will be desolvated.

2. Evaporation System

Miscella will be pumped into the evaporation system after removing impurities twice. The evaporation system consists of 1st stage evaporator, 2nd stage evaporator and a stripping tower. The solvent evaporated from miscella will be recycled.

3. D.T.D.C

Wet meal after solvent extraction containing a certain amount of solvent will be conveyed to D.T.D.C for desolventizing, toasting, drying and cooling.

4. Solvent Recycling

The n-hexane evaporated from each section is recycled to the solvent tank through the condenser. The uncondensed gas enters the exhaust condenser and most of the uncondensed n-hexane is condensed. A small amount of n-hexane vapor and non-condensable gas enters the absorption tower in which n-hexane is absorbed by mineral oil. Other non-condensable gas is exhausted through the exhaust fan.

Customer Case

Packing & Delivery

Customer Feedback

Hot Searches