- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Other

-

Design Style:

-

Industrial

-

Type:

-

steel mould form traveler system, Recyclable

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BOYOUN

-

Model Number:

-

Formwork System

-

Material:

-

Steel

-

Usage:

-

Concrete Construction Support

-

Size:

-

Non-standard:custom-made

-

Certificate:

-

ISO9001

-

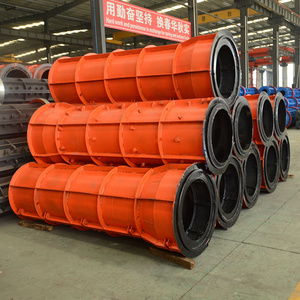

Surface:

-

Painting

-

Packing:

-

Standard Sea-transport Packing

-

Product name:

-

Concrete Steel Formwork

-

Advantage:

-

Quick Installation

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Training

-

Project Solution Capability:

-

3D model design, total solution for projects

-

Application:

-

Other

-

Design Style:

-

Industrial

-

Type:

-

steel mould form traveler system, Recyclable

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BOYOUN

-

Model Number:

-

Formwork System

-

Material:

-

Steel

-

Usage:

-

Concrete Construction Support

-

Size:

-

Non-standard:custom-made

-

Certificate:

-

ISO9001

-

Surface:

-

Painting

-

Packing:

-

Standard Sea-transport Packing

-

Product name:

-

Concrete Steel Formwork

-

Advantage:

-

Quick Installation

PRODUCT DESCRIPTION

Underslung Forming Traveler

The A/H type cable tower

underslung form traveler

is named after the shape of the cable-stayed bridge's cable tower. Its cable tower structure is similar to the letters "A/H". It consists of upper beam, front and rear inclined bar, bottom basket and formwork.

Scope of application: Suitable for bridge construction of A/H type cable towers, especially scenarios that require the pouring of

large-span and long-segment cable-stayed bridges.

Scope of application: Suitable for bridge construction of A/H type cable towers, especially scenarios that require the pouring of

large-span and long-segment cable-stayed bridges.

|

Underslung Form Traveler

|

|

|

|

|

||||

|

Typical Span of Continuous Beam

|

32+48+32m; 48+56+48m; 40+64+40m; 48+80+48m; 60+100+60m; 72+120+72m; 72+128+72m.

|

|

|

|

||||

|

Typical Length of Pier Table

|

9m; 12m; 15m; 18m

|

|

|

|

||||

|

Heaviest Cantilever Beam Girder in Tonnage

|

About 90-200T

|

|

|

|

||||

|

Cantilever Pouring Length

|

3-5m

|

|

|

|

||||

|

Material

|

Q235B, Q355B Steel.

|

|

|

|

||||

|

Standard Configuration

|

Main truss, walking system, suspension system, bottom support system, formwork system

|

|

|

|

||||

|

Options

|

Protection system (bottom support protection, full facade protection), hydraulic system, suspension accessories

|

|

|

|

||||

Successful Cases

Nanxi River Mega Bridge Project

The Nanxi River mega bridge is located in Yongjia County, Zhejiang Province. It spans the Zhu Yong Expressway and the Nanxi River, serving as a pivotal project for package 6 of the Hangzhou-Wenzhou High-Speed Railway. The bridge, measuring 481.6 meters in length, features a double-tower, double cable plane concrete cable-stayed bridge with a span of (40.5+79.5+240+79.5+40.5) meters and a semi-floating system. The main beam is constructed using the underslung form traveler for concrete casting, while cantilever form travelers are employed for approach bridges.

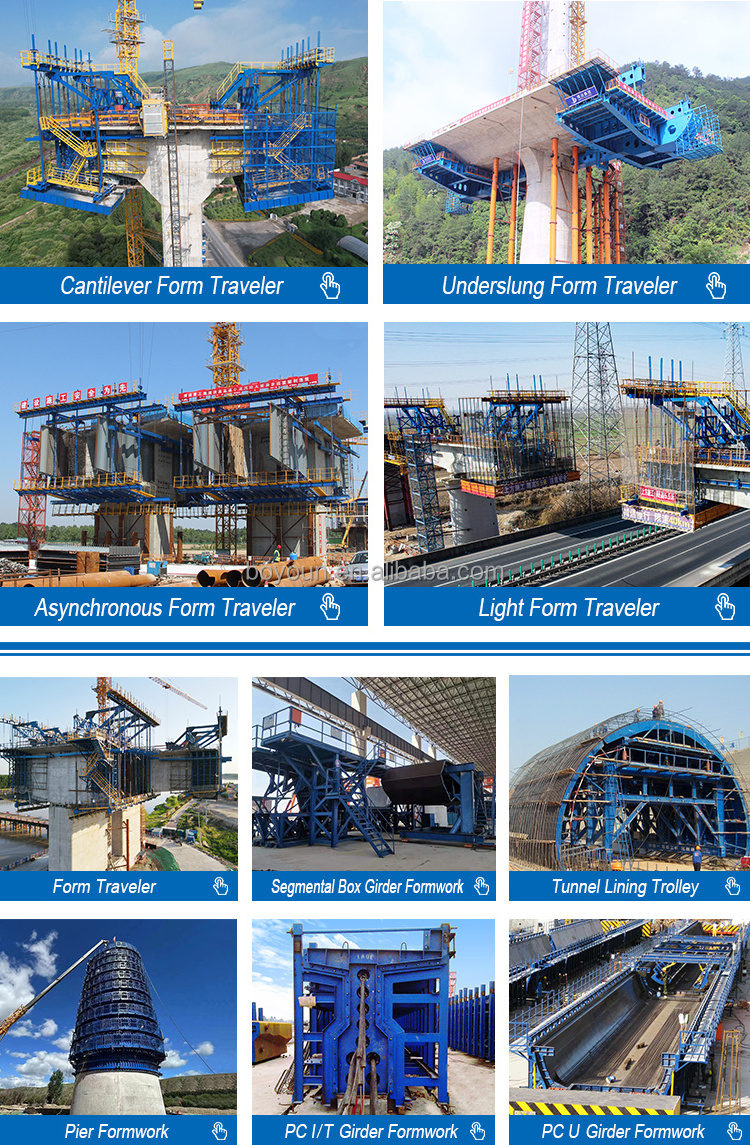

RELATED PRODUCTS

WHY CHOOSE US

Why selecting Boyoun CFT?

2. Main nodes are connected by pins, facilitating easy assembly and disassembly, and saving time and labor resources.

3. Ensure safety through Midas modeling and force calculation.

4. Light weight and can move flexibly and smoothly.

5. High stiffness and small deformation.

6. Standardization rate exceeds 90%, demonstrating high versatility.

CERTIFICATIONS AND HONORS

COMPANY PROFILE

Introduction of Shandong Boyoun Industries Co., Ltd.

Shandong Boyoun Heavy Industries Co., Ltd, founded in 2006 , is committed to supplying a wide range of formwork for bridge, viaduct and tunnel engineering. The headquarter and main factory are located in Binzhou city of Shandong China, with International Department located in Beijing.

The annual output is more than

75,000 tons

, Boyoun has been qualified by ISO QM System since its foundation. More than

30 patents have been approved each year

. Main products cover: Cantilever Form Traveller, Underslung Form Traveler, Precast Segmental Box Girder Formwork, PC I shape T shape U shape Girder Formwork, Tunnel Lining Trolley, Pier formwork, etc. Besides supplying the formwork, customized services like technical proposals, on-site installation supervision, buying back and rental service can be also provided by Boyoun.

Replying on advanced processing machines, such as laser cutter and automatic welding robot, Boyoun has completed over

1,200 projects

Worldwide,including China-Maldives Friendship Bridge in Maldives, Padma Bridge and BRT Dhaka in Bangladesh, Pulau Balang Cable Stayed Bridge and Kendari Cable Stayed Bridge in Indonesia, East Coast Railway in Malaysia, Malaysia MRT 2 and LRT 3, BGC-Ortigas Bridge in Philippines, No.6 Expressway and Tha Chin River Bridge in Thailand, North-South Corridor Project in Singapore, etc.

Painting Workshop

Ready for Painting

Welding Workshop

DELIVERY

FAQ

Q1. How to connect large rods?

It is simple and convenient to assemble large rods using bolt connections.

Q2. What material is used for the rear anchor of the form traveler?

The rear anchorage of the form traveler is made of precision-rolled rebar, which has clear stress and a safe and reliable

structure.

structure.

Q3. What are the characteristics of the single box single cell cantilever form traveler?

The characteristics of the single box single cell cantilever form traveler mainly include: simple structure, clear force, light

weight, complete structure, easy operation, safety and reliability, etc. At the same time, it also has high construction

efficiency, can shorten the construction period and reduce project costs.

weight, complete structure, easy operation, safety and reliability, etc. At the same time, it also has high construction

efficiency, can shorten the construction period and reduce project costs.

Hot Searches