- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

33 rpm

-

Place of Origin:

-

China

-

Brand Name:

-

SG

-

Voltage:

-

defalut 380V/3PH/50HZ; can choose

-

Dimension(L*W*H):

-

Dofferent

-

Power (kW):

-

2.2

-

Weight:

-

4.0 KG

-

After-sales Service Provided:

-

Video technical support

-

Hauling speed:

-

Max speed : 1-15m/min

-

Driving motor power:

-

2.2kw, frequency conversion

-

Extruder:

-

single or double

-

suitable materia:

-

PE Pellet

-

Usage:

-

new

-

Color:

-

can choose

-

Inverter:

-

Different

-

Output (kg/h):

-

130 - 230 kg/h

-

Certification:

-

ISO 9001 CE

-

Marketing Type:

-

New Product 2022

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

28:1

-

Screw diameter (mm):

-

50 mm

-

Screw Speed (rpm):

-

33 rpm

-

Place of Origin:

-

China

-

Brand Name:

-

SG

-

Voltage:

-

defalut 380V/3PH/50HZ; can choose

-

Dimension(L*W*H):

-

Dofferent

-

Power (kW):

-

2.2

-

Weight:

-

4.0 KG

-

After-sales Service Provided:

-

Video technical support

-

Hauling speed:

-

Max speed : 1-15m/min

-

Driving motor power:

-

2.2kw, frequency conversion

-

Extruder:

-

single or double

-

suitable materia:

-

PE Pellet

-

Usage:

-

new

-

Color:

-

can choose

-

Inverter:

-

Different

-

Output (kg/h):

-

130 - 230 kg/h

-

Certification:

-

ISO 9001 CE

-

Marketing Type:

-

New Product 2022

Product Description

Application

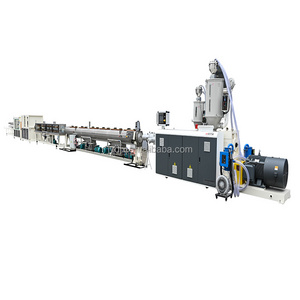

It is fully computer controlled,automatic production line (200-600) . It has features of high and stable output capacity, and highly automatic operation. According to the material situation, for HDPE, you can choose high efficient single screw extruder. For PVC, you can choose conical twin screw extruder or parallel twin screw extruder: The forming system of this line consists of mould and corrugator. The mould blocks can be easily changed and they are equiped with air or water cooling system. The production line can also be equipment with siemens company logic control system.

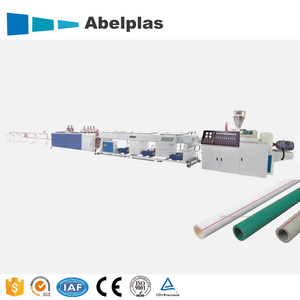

PE, PP, PVC single/double wall corrugated pipe machine/ corrugated pipe extrusion line/ corrugated pipe production line

You can see video for corrugated pipe extrusion line at our WEBSITE !!!

Detailed Images

Working flow of PE, PP, PVC single/double wall corrugated pipe machine/ corrugated pipe extrusion line/ corrugated pipe production line

Plastic extruder → mould → forming machine →pull off machine → winder

The whole machine

1.plastic extruder

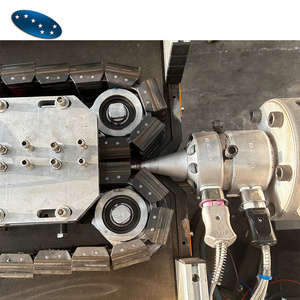

2.mould

3.Corrugating machine

4.Pull off machine

5.winder

Size Information

|

|

SG-LV

|

SG-LVA

|

|

POWER

|

11KW

|

15KW

|

|

MOULD SPECIFICATON

|

200MM-400MM

|

300MM-600MM

|

|

MOULD MATERIAL

|

special alumium alloy

|

special alumium alloy

|

|

mould perimeter

|

7m

|

7m

|

|

mould cooling way

|

air cooling

|

air cooling

|

|

production speed

|

0.5m-2m/min

|

0.5m-2m/min

|

|

production material

|

pvc/hdpe

|

pvc/hdpe

|

|

main machine

|

TWin-screw extruder

|

TWin-screw extruder

|

|

|

/single screw extruder

|

/single screw extruder

|

Related Products

Packing&Shipping

1.The machine body is covered by waterproof film firstly, and then fixed on exported wooden pallets with bolts and wires.

2.The electric controlling parts and spare parts are loaded separately in wooden box.

3.The auxiliary equipments are packaged in wooden box as well.

4.All wooden material is fumigation certificated and safe for exporting to all over the world.

Company Introduction

FAQ

For choosing proper machine and saving your time, please read below questions carefully and send your inquiry soon , thanks .

1.what material will you use ? PP PE or PVC ?

2. What is the diameter (mm) of this PE,PP, PVC corrugated pipe production line? Is it single wall or double wall?

3. What is your power standard (V, Hz, Phase)?

4. Other requirements about the machine you want.

Turnkey project service:

1. we will provide all the machines for the complete production according to customer's requirements.

2. we will provide complete service for factory layout and other information to help customer to build the factory.

3. we can also provide the raw material to the customer if you need.

4. we will provide good service for machine installation and training, until the customers can run the machines and make stably production.

5. Except one year quality guarantee, we will provide after-sell service for all the life.

6. For long-term cooperation, we always provide good quality, good price and good service to customer. we are the professional and trustable supplier for turnkey projects. Let us do win-win business together.

By the way , Our company is about 110 km away from Shanghai(1.5 hour bus driving from shanghai airport) . Warmly welcome you to visit our factory at any time.

Hot Searches