- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

3000kg

-

Size:

-

5.1*3.4*4.0

-

Power:

-

12.5 Kw

-

Productivity:

-

80000L/Hour

-

Weight (KG):

-

4000 kg

-

Brand:

-

JORSUN

-

Max Capacity:

-

80 m3/h

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Video technical support

-

Application::

-

Electroplating, Electronic Semiconductor,Integrated Circuit Plate

-

Keywords:

-

cone shape sludge hoppers

-

Technology:

-

shallow tank theory

Quick Details

-

Place of Origin:

-

Shanghai, China, Shanghai

-

Brand Name:

-

JORSUN

-

Material:

-

Mild steel, SUS304/316, FRP stainless ateel, Carbon Steel, stainless steel,SUS304/316, FRP,

-

Weight:

-

3000kg

-

Size:

-

5.1*3.4*4.0

-

Power:

-

12.5 Kw

-

Productivity:

-

80000L/Hour

-

Weight (KG):

-

4000 kg

-

Brand:

-

JORSUN

-

Max Capacity:

-

80 m3/h

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Video technical support

-

Application::

-

Electroplating, Electronic Semiconductor,Integrated Circuit Plate

-

Keywords:

-

cone shape sludge hoppers

-

Technology:

-

shallow tank theory

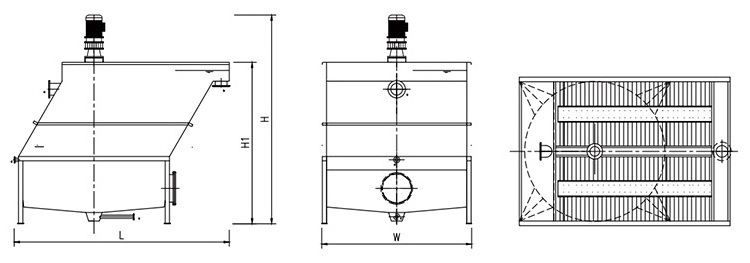

LST Working Process

Lamella Clarifier system is based on the "shallow tank theory" of Professor Hazen put forward by the early 20th century,

and the core theory is that sedimentation performance depends on effective settling area, nothing to do with sedimentation depth.

Lamella clarifier system settling area is inclined plate projection area accumulation .

Features

1. Customized design, meet variable requirements.

2. Fairly adapt to the sewage with large amount of sedimentation ( rich particles, greese and colliod ).

3. Fully (100%) manufactured in the factory, and no need secondary welding, also it takes 2 workers 3h to assemble.

4. Indoor or outdoor layout (environment temperature/Fahrenheit should be over 0°C /32°F,

water temperature/Fahrenheit should be no less than 42°C/107.6°F).

5. Apply to automatic & continuous operation.

6. Replace traditional secondary clarifier with biological treatment.

LST Application Field

1. Industrial wastewater treatment: Integrated Circuit Plate, Electronic Semiconductor, Electroplating, Chemical Wastewater etc.

2. Wastewater Treatment Plant (WWTP): upgrade .

3. River, lake treatment.

Superiority

1. Higher efficiency, smaller footprint .

2. Equal water distribution and synchronous water collection .

3. No blind angle and vortex.The whole tank is in operation of equal .

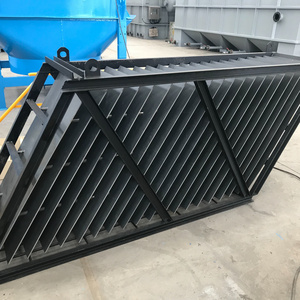

4. No blocking Inclined plates : p lates are designed for 60 degrees angle with the board spacing between 80 ~ 100 mm, as well as the back-washing device .

5. Strong and durabl e: adopt 5-6mm hard UPVC plates , 8 mm PP plates , stainless steel plates as separation plate, module embedded installation,

in this manner it could keep high quality and be easy disassembling and maintenance.

6. Sludge discharge smoothly: no blind angle, and the sludge is discharged by negative pressure suction.

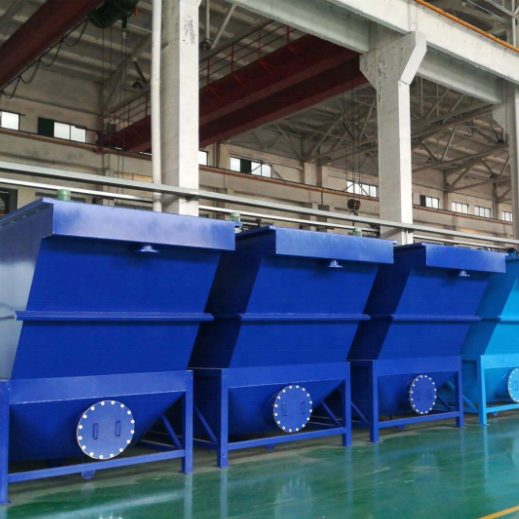

7. LST1 is a clarififier with one or more cone shape sludge hoppers.

8. LST2 is a clarififier with sludge scraper and one or more sludge hoppers which pocess great advantage for packaged in large flow rate .

Applied Industry

1. Electronic & Electroplating wastewater.

2. Paper & Pulp wastewater.

3. Industrial process water.

4. Treatment before filtration.

5. Filtrate and backwash water.

6. River or lake clarification.

|

Model |

Capacity |

Dimension(m) |

Sludge scraper |

Nozzle list(DN) GB/JIS/ANSL |

||||||

|

(m3/h) |

L |

W |

LST1 H |

LST2 H/H2 |

LST2 kw |

Inlet |

Outlet |

Sludge outlet |

Backwash |

|

|

LST-005 |

~5 |

2.6 |

1.6 |

2.9 |

3.4/2.5 |

0.25 |

80 |

50 |

50 |

50 |

|

LST-010 |

~10 |

3.4 |

1.8 |

3.6 |

3.8/3.0 |

0.25 |

100 |

80 |

50 |

50 |

|

LST-020 |

~20 |

3.4 |

2.2 |

3.6 |

3.8/3.0 |

0.25 |

150 |

150 |

50 |

50 |

|

LST-030 |

~30 |

4.2 |

2.2 |

4.0 |

3.8/3.0 |

0.25 |

150 |

150 |

50 |

50 |

|

LST-040 |

~40 |

4.0 |

2.8 |

4.0 |

3.8/3.0 |

0.25 |

200 |

200 |

50 |

50 |

|

LST-050 |

~50 |

6.3 |

2.2 |

4.0 |

3.8/2.0 |

0.25 |

200 |

200 |

50 |

50 |

|

LST-060 |

~60 |

4.8 |

3.0 |

4.0 |

3.8/3.0 |

0.25 |

250 |

200 |

50 |

50 |

|

LST-080 |

~80 |

5.1 |

3.4 |

4.0 |

4.0/3.2 |

0.25 |

250 |

250 |

80 |

50 |

|

LST-090 |

~90 |

6.3 |

3.0 |

4.0 |

4.0/3.2 |

0.25*2 |

250 |

250 |

80*2 |

50 |

|

LST-100 |

~100 |

7.1 |

3.0 |

4.0 |

4.0/3.2 |

0.25*2 |

250 |

250 |

80*2 |

50 |

|

LST-120 |

~120 |

8.3 |

3.0 |

4.0 |

4.0/3.2 |

0.25*2 |

300 |

300 |

80*2 |

50 |

|

LST-150 |

~150 |

9.8 |

3.2 |

2.9 |

4.0/3.2 |

0.25*2 |

350 |

300 |

80*2 |

50 |

ABOUT JORSUN

- Jorsun established in Shanghai 2004.

- Jorsun pursues the aim of “focus on separation,service for environment”. Committed to separation technology research and development, marketing,equipment manufacturing and services.

- Jorsun main products and services include: XAF® series DAF, Lamella Clarifier, integrated applications.There are more than 1,000 successful references in the worldwide over 40 countries till now, such as paper,petrochemical, printing and dyeing, leather, pharmaceuticals, iron and steel, electronics, food, rivers and community landscape water purification, WWTP advanced treatment and recycled water reuse and some other industries or fields.

- Jorsun adheres to the integrity,profession, safety, innovation company value, to meet customer demands ,has won more extensive customers.

- Jorsun is in pursuit of high quality, continuous innovation,determined to contribute more to environmental protection,become a leader of separation in water fields.

FAQ

Q: How to buy your idea products?

A:You can provide us your water sources, water quality, flow rate and ground area (connect us for more details).

Q:How to pay?

A:TT and L/C are acceptable and TT will be more appreciated. 30% deposit before producing, 70% balance before loading by TT.

Q:What is the delivery time?

A:It depends on order quantities. Generally speaking, the delivery time will be within 4 to 6 weeks.

Q:How to pack the products?

A:We use standard package. If you have special package requirements, we will pack as required, but the fees will be paid by customers.

Q:How to keep your equipments from corrosion?

A:We use the world-famous paint, like SigmaCoatings,PainBow,etc. What's more, we paint strictly according to the standard process.

Q:How do you manufacture your equipment?

A:Our machining technology includes laser/plasma cutting, automatic welding,CNC cutting and bending.

Q:How to install after the equipments arriving destination?

A:We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you. However, the visa fee, air tickets, accommodation, wages will be paid by buyers.