- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LYM-Liye Machinery

-

Power (kW):

-

4

-

Weight (KG):

-

1100

-

Applicable Industries:

-

metal pipe machining enterprise

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

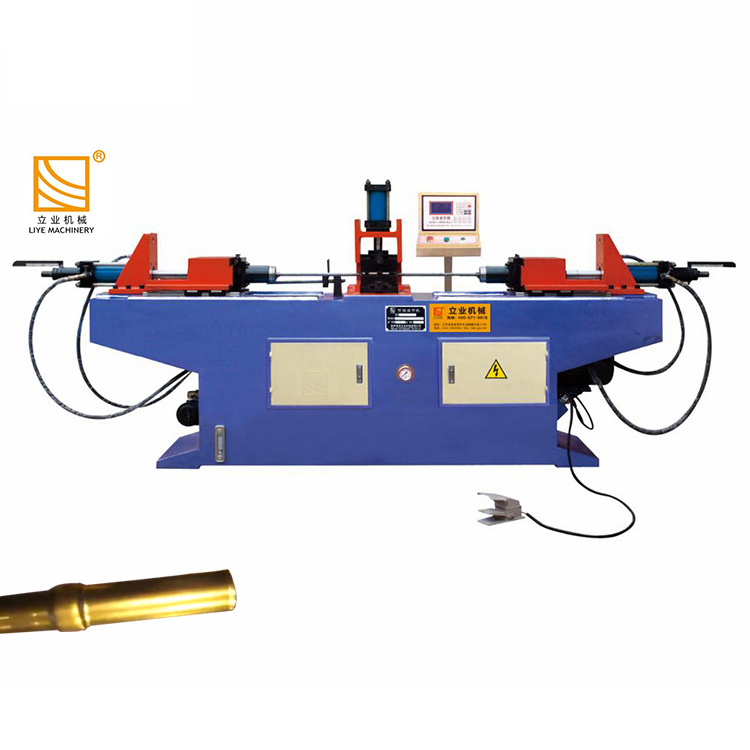

SG40NC Tube end processing end forming pipe expending machine

-

Measurement size of machine:

-

Customer requirement

-

Weight of machine:

-

Customer requirement

-

Maximum working process:

-

110mm (customizable)

-

Oil pump:

-

23L

-

Motor power:

-

4kw

-

Hydraulic pressure:

-

12Mpa

-

Control circuit:

-

24V

-

Input voltage:

-

380V±10% 50HZ Three-phase power (customizable)

Quick Details

-

Max.Shrinking Capacity (Thickness)(mm):

-

2 mm

-

Max.Shrinking Capacity (Diameter)(mm):

-

40 mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LYM-Liye Machinery

-

Power (kW):

-

4

-

Weight (KG):

-

1100

-

Applicable Industries:

-

metal pipe machining enterprise

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

SG40NC Tube end processing end forming pipe expending machine

-

Measurement size of machine:

-

Customer requirement

-

Weight of machine:

-

Customer requirement

-

Maximum working process:

-

110mm (customizable)

-

Oil pump:

-

23L

-

Motor power:

-

4kw

-

Hydraulic pressure:

-

12Mpa

-

Control circuit:

-

24V

-

Input voltage:

-

380V±10% 50HZ Three-phase power (customizable)

pipe expending machine

SG40NC Tube end processing end forming pipe expending machine

Sample:

Specification:

| SG Pipe end forming machine | |

| Specification/model | SG40NC (Dual head type ) |

| Input voltage | 380V±10% 50HZ Three-phase power (customizable) |

| Control circuit | 24V |

|

Maximum forming pipe diameter x thickness (Iron pipe ) |

Φ40*2mm |

| Maximum working process | 110mm (customizable) |

| Machine head spacing | Customer requirement |

| Oil pump | 23L |

| Motor power | 4kw |

| Hydraulic pressure | 12Mpa |

| Measurement size of machine | Customer requirement |

| Weight of machine | Customer requirement |

Feature:

1. The product is controlled by microcomputer and driven hydraulically. It applies Chinese character display and man-machine conversation operation, and can be operated manually or semi-automatically. One-point foot switch has two functions, startup and emergency stop.

2. With double-station arrangement, pipe end forming machine can shrink the tube for two times simultaneously. Applying linear guideway as the carrier, the product can ensure action without abrasion and ensure good repeatability.

Processing shapes: convex-shaped, concavity-shaped, nodular shape, long partial shape, square shape, topological shape, oblique shape, V-shape, cracking type and flat type. The shape of the mould shall be subject to the object to be processed.

3. The distance between two ends can be adjusted according to the length of tube. (limited to the double-end forming machine only)

4. Single-end clamping or double-end clamping can be carried out according to length of the tube.

5. The product has characteristics including easy operation, stable performance, high work efficiency and high safety factor and it is an ideal device for tube processing industry.

Standard accessories

1. One pair of mould (shrinkage mould and clamping mould)

2. One set of common tools