- Product Details

- {{item.text}}

Quick Details

-

Effective Volume:

-

3.5-10CBM

-

Dimension(L*W*H):

-

2.1*2.3*1.9m

-

Voltage:

-

220v/380v

-

Power:

-

7.5kw

-

Weight (KG):

-

1600

-

After-sales Service Provided:

-

No overseas service provided

-

Color:

-

green, red,blue...

-

Weight:

-

2.8 T

-

Capacity:

-

1000 kg/10 hours

-

Size:

-

2.8*2.0*2.3m

-

Raw material:

-

wood sawdust briquette, wood log, bamboo

-

Type:

-

Horizontal type

-

input:

-

2500kg raw material one stove

-

Name:

-

bamboo charcoal carbonization kiln

Quick Details

-

Place of Origin:

-

Henan, China

-

Core Components:

-

seal packing material

-

Brand Name:

-

Sanjin

-

Effective Volume:

-

3.5-10CBM

-

Dimension(L*W*H):

-

2.1*2.3*1.9m

-

Voltage:

-

220v/380v

-

Power:

-

7.5kw

-

Weight (KG):

-

1600

-

After-sales Service Provided:

-

No overseas service provided

-

Color:

-

green, red,blue...

-

Weight:

-

2.8 T

-

Capacity:

-

1000 kg/10 hours

-

Size:

-

2.8*2.0*2.3m

-

Raw material:

-

wood sawdust briquette, wood log, bamboo

-

Type:

-

Horizontal type

-

input:

-

2500kg raw material one stove

-

Name:

-

bamboo charcoal carbonization kiln

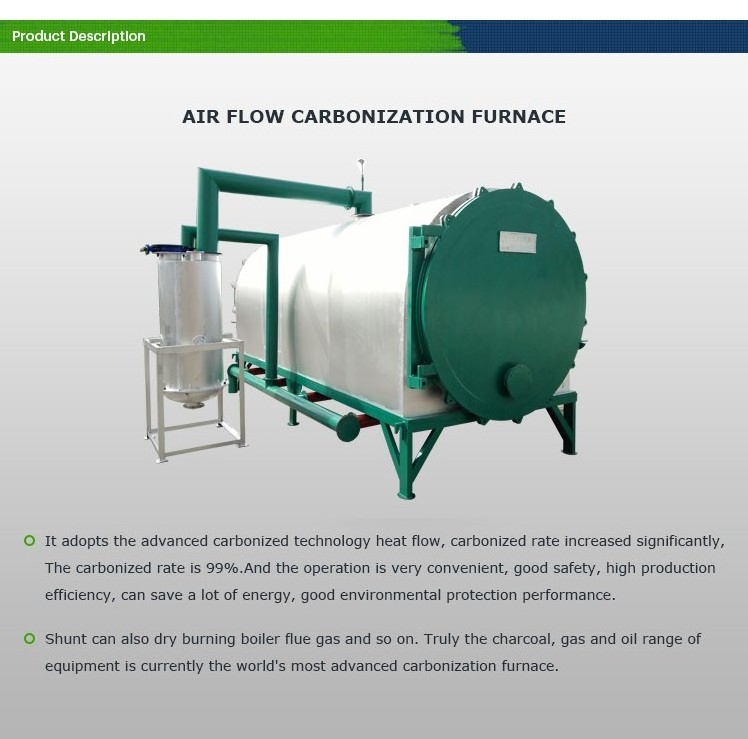

Introduction of the bamboo charcoal carbonization kiln:

60605952707 60605952707 60605952707 60605952707 60605952707 60605952707

Sanjin brand bamboo charcoal carbonization kiln was developed by our factory latest modular air coking furnace, more than a day can be carbonized furnace, greatly shorten the production cycle, improve the efficiency of charcoal production, is an ideal equipment of large and medium scale charcoal production of charcoal.It uses a unique storage chamber structure, make full use of the flue gas produced by carbonization.In addition to their use of the stove, achieve energy conservation and environmental protection requirements.Energy-saving airflow carbonization furnace, simple and convenient, need not power and mobile production.It is an ideal equipment of family scale production.

Application of the bamboo charcoal carbonization kiln

--Biomass( from urban garbage sorting) carbonization

--Stem/cell of agriculture plants carbonization: palm leaf/shell, rice husk, cocoanut shell and etc.

--Industry papermaking scrap carbinization

--Municipal sludge treatment

--Soil improvement

Advantage of the bamboo charcoal carbonization kiln

:

1.It adopts the advanced carbonized technology heat flow,carbonized rate increased significantly,

2.The carbonized rate is about 80%, up by 99%.And the operation is very convenient, good safety,

3.high production efficiency,can save a lot of energy, good environmental protection performance.

4.Shunt can also dry burning boiler flue gas and so on.Truly the charcoal,gas and oil range of equipment.

5.Is currently the world's most advanced carbonization furnace

features of bamboo charcoal carbonization kiln

1. Due to its design principle of rotary type, reduce its carbonization time.

2. It can use different material as the fuel.

3. Saving energy, it can reuse the smoke produced during the process of carbonization.

4. Compare with the hoist type carbonization, its biggest advantage is it doesn’t need any hoist

equipment.

|

Model

|

Capacity

|

Dimension

|

Weight

|

|

120

|

2000kg/24h

|

2.86*1.6*2.1m

|

1.68t

|

|

170a

|

4000kg/24h

|

2.85*2.1*2.1m

|

3t

|

|

170b

|

7000kg/24h

|

4.6*2.1*2.1m

|

3.5t

|

Specifications of the bamboo charcoal carbonization furnace

1.Raw material:wood branches,wood logs, bamboo, coconut shell, charcoal stick.wood waste etc.

2.Can customized the model according to your requir

3.Smokeless and energy-saving

To improve the design of the charcoal carbonization furnace, in order to prevent gas leakage, the oven door with graphite packing seal, greatly enhancing the effect of carbonization

1.In the carbonization process ,can produce combustible gas,can recycle these gas.These gas delivery to the white tank through No.1 pipeline,then open the valve of the No.2 pipeline, these gas can reach to the bottom of the furnace through the No.2 pipeline.At the No.4 valve, you can be connected to a pipeline at the No.4 valve, so that can use the extra gas,these gas can cooking, burnning boiler etc.So can save some cost, it is enery-saving.

2.NO5This is shunt tank, at the Nbottom(NO.5) can collect the wood tar.

Gongyi city sanjin charcoal factory was built in 1988, is located in gongyi city in henan province.Is a technology leading enterprises, the People's Republic of China import and export enterprises, charcoal machine won the national patents 10.Company main products: charcoal, charcoal machine automation equipment, series of straw gasifier, straw gasification, carbon powder molding machine, grinder, sawdust dryer, stick machine, such as coking furnace large biomass equipment production line.

our service of the bamboo charcoal carbonization kiln

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. after sending, we will track the products for you once every two days, until you get the products. When you got the

goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer

the solve way for you.

Q&A of the bamboo carbonization stove

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages

before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 30 to 60 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.