- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

COLORDOWELL

-

Model Number:

-

1018A

-

Type:

-

hot melt glue

-

The operating temperature (°C):

-

140~170

-

Colour:

-

Transparent

-

Shape:

-

Sheet shape or flake

-

Feature:

-

Relatively low price but high quality

Quick Details

-

CAS No.:

-

1018A

-

Other Names:

-

hot melt glue

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

COLORDOWELL

-

Model Number:

-

1018A

-

Type:

-

hot melt glue

-

The operating temperature (°C):

-

140~170

-

Colour:

-

Transparent

-

Shape:

-

Sheet shape or flake

-

Feature:

-

Relatively low price but high quality

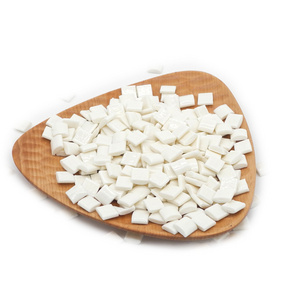

Product Paramenters

|

Name

|

Book Binding Hot Melt Adhesive(Thermoplastic Resin Adhesive)

|

|

Colour

|

Transparent

|

|

Shape

|

Sheet shape or flake

|

|

Logo

|

WD

|

|

Basic material

|

Ethylene-vinyl acetate copolymer(EVA) and ESTER GUM

|

|

Function

|

Be used in spine binding of the book with general paper(80g)

|

|

Feature

|

Relatively low price but high quality

|

|

Quality

|

ESTER GUM can be excellently compatible with EVA and improve adhesiveness of the production. Also it has strong resistance to

corrosion, moisture and impact |

|

The operating temperature (°C) :

|

140~170

|

|

Packing

|

25KG lined with plastic sacks

|

|

Storage

|

Store in drying gloomy and cold place, avoid blasting bask in the sun and high temperature baking. During transportation should be

moistureproof and prevent heat |

Details Images

Products Description

Hot melt adhesive production process

1-Crusher; 2-Kneader;3-Insulation hopper; 4-Extruder; 5-Die; 6-Steel cooler; 7-Plastic cutting machine

The hot glue that used in bookbinding is made up from EVA, high quality glycerinum and C5resin.

The hot glue that used in bookbinding is made up from EVA, high quality glycerinum and C5resin.

Features:

1.Good fluidity: Bubbles and hollow back won’t appear if proper controlling after bookbinding with the hot melt adhesive.

2.High softening point: Suitable for high-speed binding.

3.Long opening time: The paper needs to be wide with large binding tension.

4.Environmental thermosol particles: We strictly control our craft to avoid producing smoke, gas and bad smell during the process

of binding.

5.Good stability;Its adhesive strength can still remain after 24 hours’ under the temperature of one hundred and eighty degrees

centigrade.

6.Popular among printing houses.

2.High softening point: Suitable for high-speed binding.

3.Long opening time: The paper needs to be wide with large binding tension.

4.Environmental thermosol particles: We strictly control our craft to avoid producing smoke, gas and bad smell during the process

of binding.

5.Good stability;Its adhesive strength can still remain after 24 hours’ under the temperature of one hundred and eighty degrees

centigrade.

6.Popular among printing houses.

Recommend Products

Product packaging

Exhibition

Hot Searches