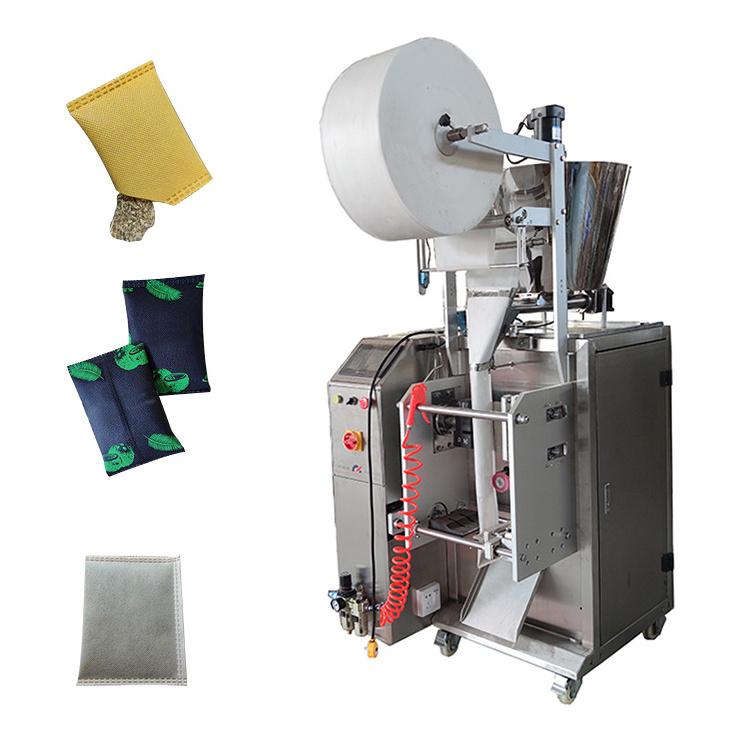

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Boom

-

Dimension(L*W*H):

-

900*1000*1700mm

-

Weight:

-

300 KG

-

Keywords:

-

Automatic non-woven packaging machine

-

Filling Range:

-

1-200g

-

Form of Measurement:

-

Measuring cup or screw

-

Packing Speed:

-

30-50 bags/min

-

Bag-making Size:

-

L(40-200)*W(40*140)mm

-

Sealing type:

-

Three side seal, back seal or four side seal (customized )

Quick Details

-

Application:

-

APPAREL, Chemical, Cigarettes, Commodity, Food, Textiles

-

Packaging Material:

-

Paper, Plastic

-

Voltage:

-

220V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Boom

-

Dimension(L*W*H):

-

900*1000*1700mm

-

Weight:

-

300 KG

-

Keywords:

-

Automatic non-woven packaging machine

-

Filling Range:

-

1-200g

-

Form of Measurement:

-

Measuring cup or screw

-

Packing Speed:

-

30-50 bags/min

-

Bag-making Size:

-

L(40-200)*W(40*140)mm

-

Sealing type:

-

Three side seal, back seal or four side seal (customized )

Products Description

Products Description

1.

Ultrasonic non-woven packaging machine adopts ultrasonic cold sealing technology, for products that need to use cold sealed non-woven fabric as packaging film, the use of this technology to seal the edge firmly, no powder leakage, safe and reliable.

2. English and Chinese display PLC control system, just set the menu on the display screen to set parameters (filling amount bag length, etc.), you can control the system automatically match the packaging action, easy to operate, easy to control.

3. The packaging machine can automatically complete the measurement, bag making, filling, sealing, cutting, counting and other work in the packaging process, automatic packaging molding.

4. In the PLC screen parameters can be set fixed package cutting or even package cutting, the operation is flexible and

convenient.

5. The packaging film part adopts the self-weight motor film feeding structure, the length of the packaging film feeding film is doubled, and the bag is smooth and good.

6. Stepper motor drive, pull bag stable and reliable, speed can be selected.

7. When the packaging film colored calibration mark, the bag making process can achieve photoelectric automatic detection, positioning, sealing, cutting off, to ensure the integrity of the bag making pattern.

8. The use of stable quality accessories, low noise, low failure rate, long service life.

2. English and Chinese display PLC control system, just set the menu on the display screen to set parameters (filling amount bag length, etc.), you can control the system automatically match the packaging action, easy to operate, easy to control.

3. The packaging machine can automatically complete the measurement, bag making, filling, sealing, cutting, counting and other work in the packaging process, automatic packaging molding.

4. In the PLC screen parameters can be set fixed package cutting or even package cutting, the operation is flexible and

convenient.

5. The packaging film part adopts the self-weight motor film feeding structure, the length of the packaging film feeding film is doubled, and the bag is smooth and good.

6. Stepper motor drive, pull bag stable and reliable, speed can be selected.

7. When the packaging film colored calibration mark, the bag making process can achieve photoelectric automatic detection, positioning, sealing, cutting off, to ensure the integrity of the bag making pattern.

8. The use of stable quality accessories, low noise, low failure rate, long service life.

Hot Searches