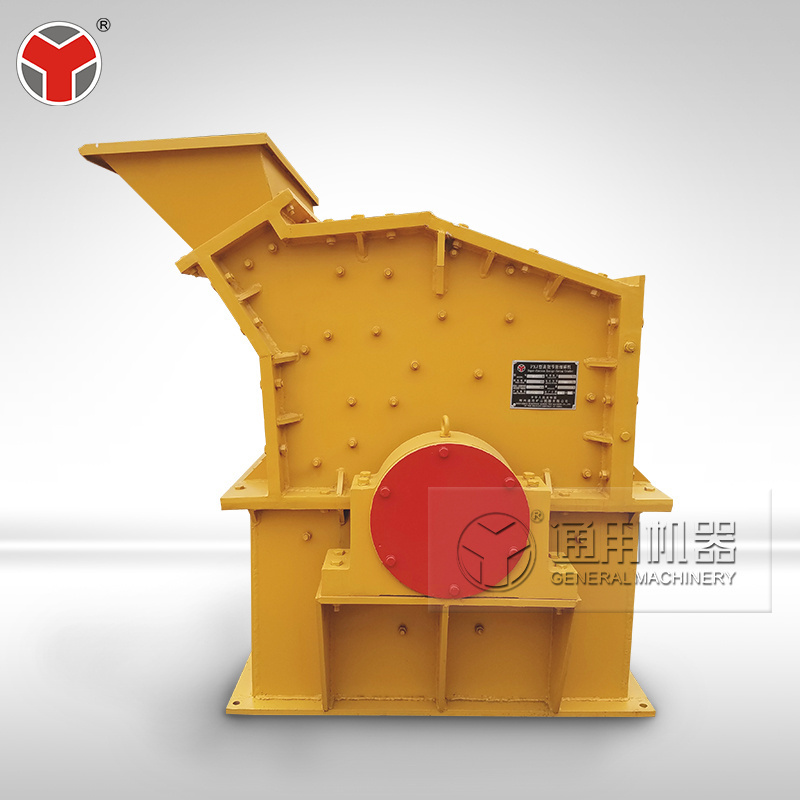

Efficient fine crusher, also known as fine crusher, PXJ sand making machine, and third-generation sand making machine, is a new generation of efficient fine crusher introduced by our company with advanced German technology and continuously optimized and improved based on user feedback. It is a new type of efficient sand making equipment. The universal high-efficiency fine crusher operates smoothly, with low dust and voltage, suitable for efficient fine crushing of materials with medium hardness. It adapts to the new situation of artificial mechanical sand making and is an ideal replacement product for rod grinding sand making machines and impact sand making machines.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

8600 KG

-

Marketing Type:

-

New Product 2024

-

Product name:

-

PXJ Fine Crusher

-

Keyword:

-

PXJ Fine Crusher

-

The Machines classification:

-

Building Stone Production Line

-

Usage:

-

Mining Crushing Stone Crusher

-

Applicaton:

-

Mining Quarry Stone Crushing Plant

-

Installation:

-

Under Engineer's Guide

-

Max feeding size:

-

80-200

-

Spare parts supply:

-

Lifelong Time

-

Color:

-

Iron Grey

-

After sale Service:

-

Life-long Service

Quick Details

-

Application:

-

Energy & Mining

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TYM

-

Weight:

-

8600 KG

-

Marketing Type:

-

New Product 2024

-

Product name:

-

PXJ Fine Crusher

-

Keyword:

-

PXJ Fine Crusher

-

The Machines classification:

-

Building Stone Production Line

-

Usage:

-

Mining Crushing Stone Crusher

-

Applicaton:

-

Mining Quarry Stone Crushing Plant

-

Installation:

-

Under Engineer's Guide

-

Max feeding size:

-

80-200

-

Spare parts supply:

-

Lifelong Time

-

Color:

-

Iron Grey

-

After sale Service:

-

Life-long Service

Product Introduction

PXJ Fine Crusher

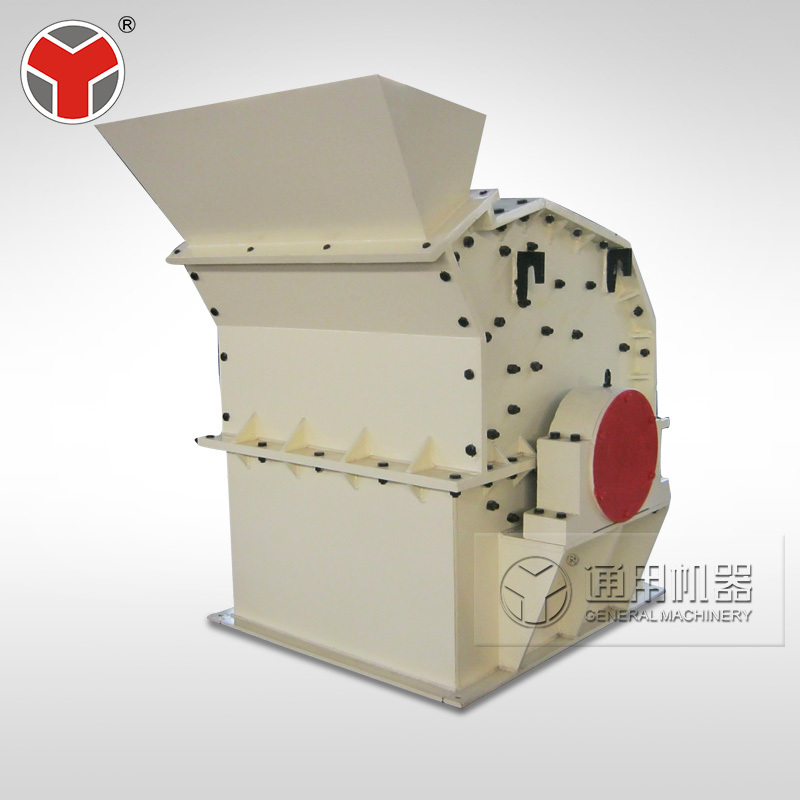

Work Pinciple

During the operation of an efficient fine crusher, materials enter the crushing chamber from the feeding port and are crushed by high-speed rotation of a rotor with a hammer head. After multiple machine and stone strikes, materials that can pass through the grate are discharged from the material port, while materials that cannot pass through are crushed until they can pass through the grate.

A reasonable combination of multi chamber crushing chambers and a new convenient dual adjustment mechanism ensure that the particle size of the discharged product is fine and uniform, with particles ≤ 3mm accounting for 90%. Convenient maintenance and repair device, using an adjustable hammer head, makes the sieve plate more agile. The wear parts are all made of new high-quality multi-element high alloy wear-resistant materials, ensuring the wear resistance and impact resistance of the hammer head and plate lining.

Applicable materials

The fine crusher is suitable for medium to hard materials such as limestone, granite, marble, basalt, iron ore, pebbles,

construction waste, diamond, calcium carbonate, silicon carbide, graphite, bauxite, concrete, manganese ore, dolomite, coal gangue, fly ash, granite, coke, iron oxide, barite, phosphate rock, etc.

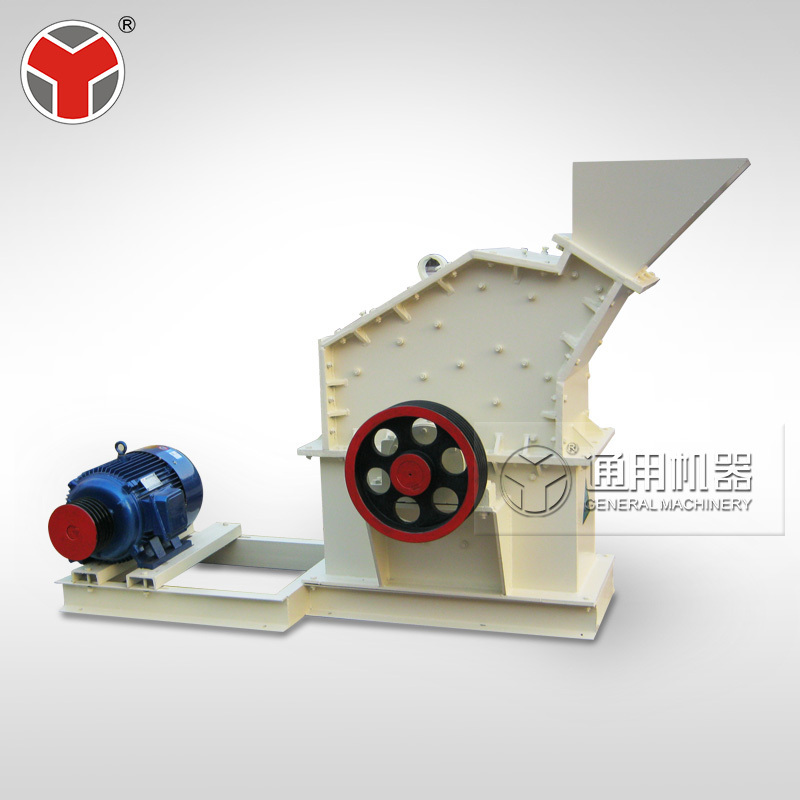

Features

1. Long working hours and high efficiency

Efficient fine crusher is a continuous operation equipment that can perform continuous processing and save downtime. Adopting the principle of impact for crushing, it has high crushing efficiency, low energy consumption, and high output.

2. Design Science, Granularity Rules

The feeding and discharging devices of the fine crusher equipment are advanced, with fewer blockage phenomena and fewer over crushing phenomena during the crushing process. Needle shaped discharge reduces by 90%, with excellent particle size, making it more suitable for application on high demand sand and gravel aggregates in construction.

3. Environmentally friendly and pollution-free

The high-efficiency fine crusher does not produce dust pollution when crushing large stones, and the mechanical noise is also reduced to lower decibels.

Technical Parameter

|

Model

|

Max.Feeding Size(mm)

|

Average Discharge Size(mm)

|

Capacity(t/h)

|

|

Motor Power(kw)

|

|

|

|

|

|

Clinkers

|

Limestone

|

|

|

|

PXJ-800*400

|

80

|

3

|

15-20

|

20-25

|

37

|

|

|

PXJ-800*800

|

80

|

3

|

25-30

|

30-40

|

45

|

|

|

PXJ-1000*1000

|

150

|

3-5

|

50-60

|

60-70

|

90

|

|

|

PXJ-1200*1000

|

200

|

3-5

|

70-80

|

80-90

|

110

|

|

|

PXJ-1200*1200

|

200

|

3-5

|

90-100

|

90-110

|

132

|

|

|

PXJ-1400*1400

|

200

|

3-5

|

110-150

|

120-160

|

160

|

|

|

PXJ-1600*1600

|

200

|

5-8

|

170-210

|

210-260

|

250

|

|

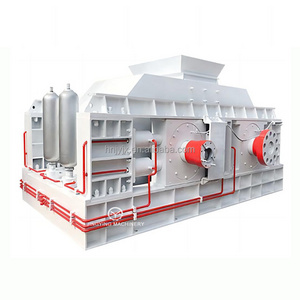

Our Customers Site

Customize solutions according to customer requirements!

We are able to design and manufacture complete crusher plants with capacity from 30tph to 500tph, and to provide optimum and most economical solutions according to customers' requirements on stone specifications, output, application, etc.

This is our stone production line in Indonesia!

The customer's requirements:

raw material: marble, capacity: 400 tons/hour, finished products: 0-5mm, 5-16mm, 16-31mm.

Equipment configuration: 2xZSW490*130 vibrating feeder, 2 PE750x1060 jaw crusher, 2xPYD2200 cone crusher, 2x3YZS2460 vibrating screen, a VSI1140 sand making machine.

raw material: marble, capacity: 400 tons/hour, finished products: 0-5mm, 5-16mm, 16-31mm.

This is our stone production line in Philippine!

The customer's requirements:

raw material: limestone, capacity: 100 tons/hour, finished products: 0-5mm, 5-10mm, 10-20mm.

Equipment configuration: ZSW380x96 vibrating feeder, PE600x900 jaw crusher, PF1214 impact crusher, 3YZS1860 vibrating feeder.

raw material: limestone, capacity: 100 tons/hour, finished products: 0-5mm, 5-10mm, 10-20mm.

Equipment configuration: ZSW380x96 vibrating feeder, PE600x900 jaw crusher, PF1214 impact crusher, 3YZS1860 vibrating feeder.

This is our stone production line in Bolivian!

The customer's requirements:

Raw material: grinite, capacity: 500 tons/hour, finished products: 0-10mm, 10-20mm, 20-30mm.

Equipment configuration: ZSW6000X1300 vibrating feeder, PE1000x1200 jaw crusher, 2 sets HP500 cone crusher, 4 sets 4YZS2470 vibrating screen.

Raw material: grinite, capacity: 500 tons/hour, finished products: 0-10mm, 10-20mm, 20-30mm.

Equipment configuration: ZSW6000X1300 vibrating feeder, PE1000x1200 jaw crusher, 2 sets HP500 cone crusher, 4 sets 4YZS2470 vibrating screen.

This is our stone production line in Vietnam!

Raw material: Barite, capacity: 40 tons/hour, finished products: 0-8mm, 8-15mm, 15-25mm.

Equipment configuration: ZSW320x90 vibrating feeder, PE400x600 jaw crusher, PYB900 spring cone crusher, 3YZS1237 vibrating screen.

Equipment configuration: ZSW320x90 vibrating feeder, PE400x600 jaw crusher, PYB900 spring cone crusher, 3YZS1237 vibrating screen.

Packing & Shipping

The package of all equipment is accord with the standard protective measures.The packing is suitable for short and long distance transportation. The moisture proof, quake proof, protected against dampness, and rustproof protection measures were taken to ensure the machine shipping to customers safely. All the machine will be packaged by plastic film.

Plastic film packaging

Large items will be wrapped in plastic film, such as jaw crusher, impact crusher, cone crusher, main mill, pipe, etc.

Box wooden packing

Small parts will be packed in wooden box, such as bolts, rubber sleeves, springs, etc

Hot Searches