- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

electrolyser

-

Name:

-

Hydrogen Generator Plant

-

Purity:

-

99.9%-99.999%

-

Working Pressure:

-

1.6Mpa

-

Hydrogen Capacity:

-

20Nm3

-

Oxygen Capacity:

-

10Nm3

-

Rated Total Current:

-

1600 A

-

Reted Total Votalge:

-

62 V

-

Cooling Water Comsumption:

-

4 T/H

-

Technological Process:

-

Water Electrolysis

-

Whatsapp/Wechat:

-

+86 131 4059 0596

Quick Details

-

Place of Origin:

-

China

-

Production Rate:

-

1-2000Nm3/h

-

Weight:

-

900 KG

-

Core Components:

-

electrolyser

-

Name:

-

Hydrogen Generator Plant

-

Purity:

-

99.9%-99.999%

-

Working Pressure:

-

1.6Mpa

-

Hydrogen Capacity:

-

20Nm3

-

Oxygen Capacity:

-

10Nm3

-

Rated Total Current:

-

1600 A

-

Reted Total Votalge:

-

62 V

-

Cooling Water Comsumption:

-

4 T/H

-

Technological Process:

-

Water Electrolysis

-

Whatsapp/Wechat:

-

+86 131 4059 0596

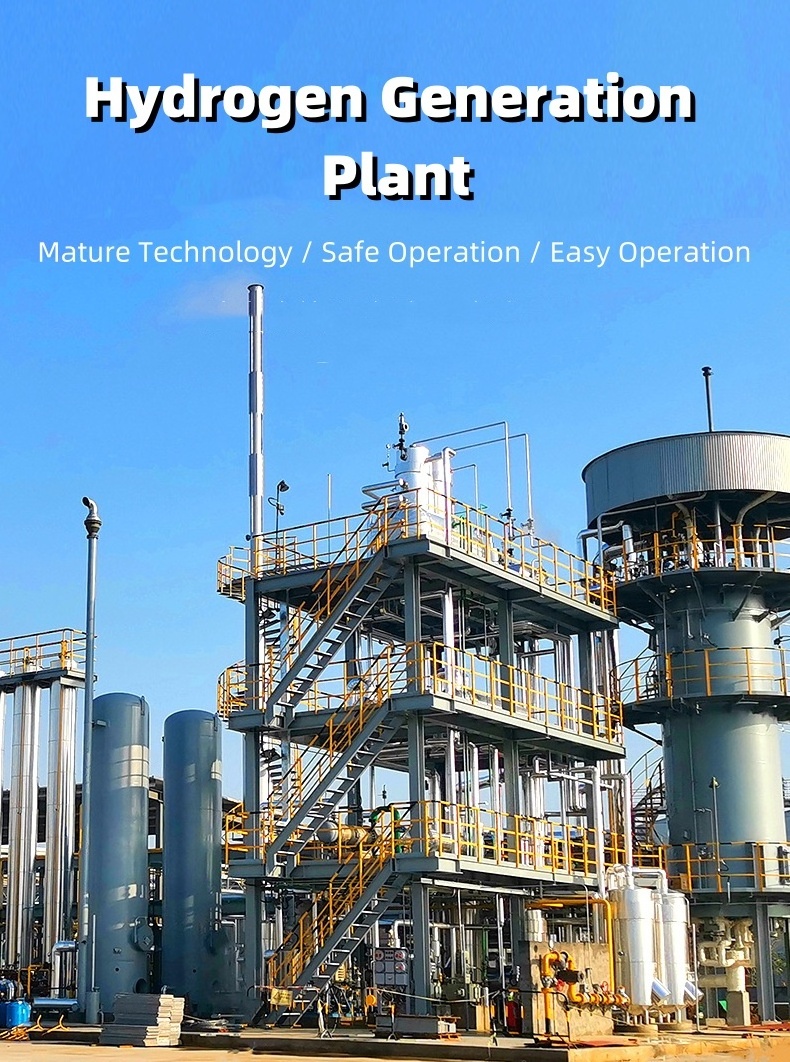

Energy Saving Hydrogen Generation/Liquidation/Drying Recovery Plant:

High Productivity 50Nm3/H Hydrogen Production Equipment Alkaline Water Kit Hydrogen Generator For New Energy Vehicle

Product Description

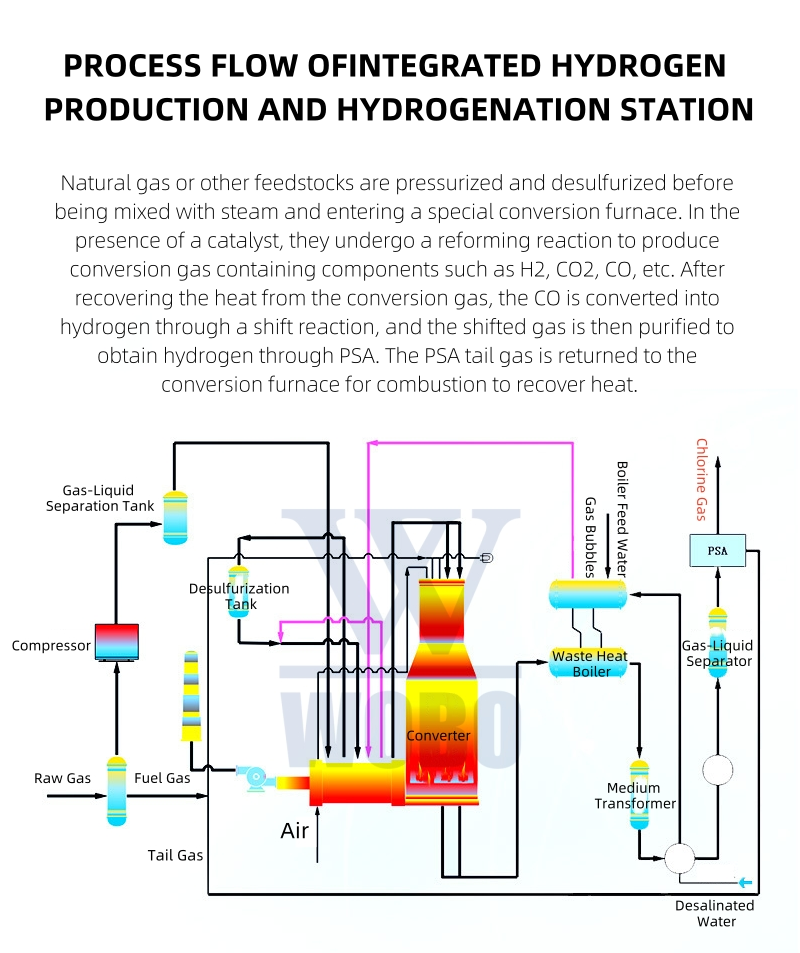

The light hydrocarbon (natural gas, dry gas, etc.) steam reforming hydrogen production device

adopts the light hydrocarbon steam reforming and PSA purification process, the hydrogen purity is high, and the raw natural gas and dry gas conversion rate is high.

Coal gasification hydrogen production device

adopts intermittent coal gasification technology and continuous coal gasification technology. Continuous coal gasification has wide adaptability of coal types, large gasification pressure range, full utilization of heat in gasifier, and large gas production per unit volume.

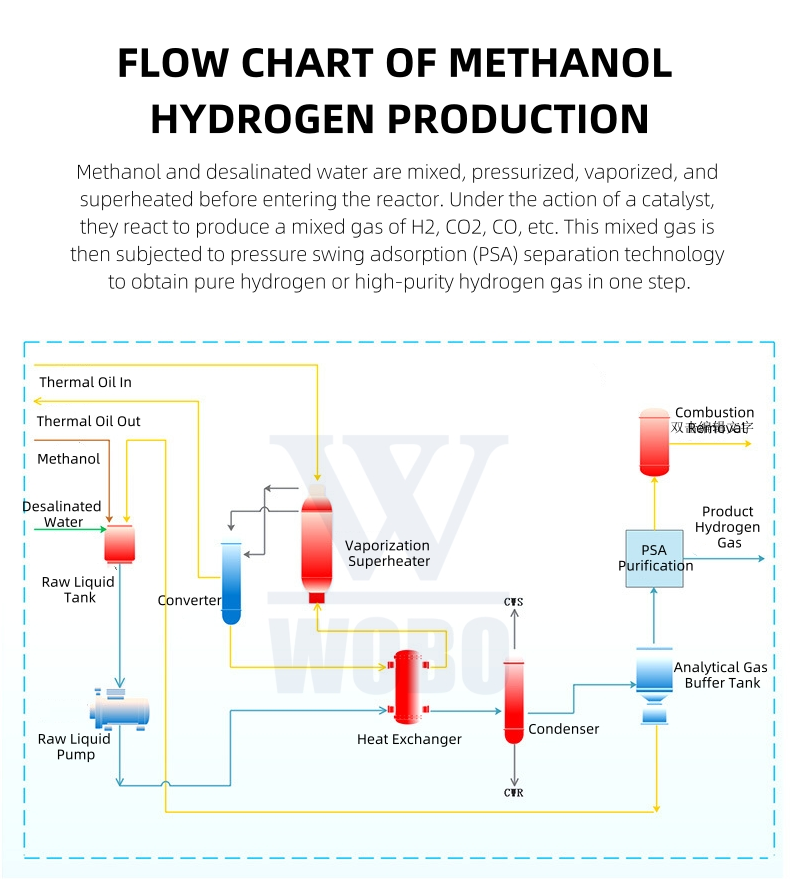

The methanol cracking hydrogen production device

adopts the methanol cracking + decarbonization + PSA purification process, with high hydrogen purity, low energy consumption, and low raw material methanol consumption, reaching 0.5kg methanol/Nm³ hydrogen.

The pure water electrolysis hydrogen production device

is a new type of green water electrolysis hydrogen production system independently developed by our institute in recent years. The hydrogen production capacity of a single device is 0.01~300Nm3/h, which can be applied to renewable energy power generation hydrogen production and hydrogen energy infrastructure. Technologies such as hydrogen production and supply at hydrogen refueling stations and natural gas blending with hydrogen have been widely used in transportation, power grid energy storage, smart microgrids, and military fields.

The pressure swing adsorption (PSA) hydrogen purification device

process are advanced and reliable, the raw material applicability is strong, and the hydrogen purity is high, the product purity is 90-99.9999%; the hydrogen recovery rate is high, and the hydrogen recovery rate is Between 60-99%; wide operating pressure range: 0.2-6.0MPaG, low energy consumption, operation flexibility up to 20-120%, the continuous operation time of the device is more than 3 years; the device has a high degree of automation, with self-adaptive adjustment, automatic fault automatic Diagnosis and other functions, it is convenient to start and stop, and has realized unmanned automatic control.

|

Ammonia decomposition hydrogen production device Parameter

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Specification

|

WB-ADH5

|

WB-ADH10

|

WB-ADH20

|

WB-ADH30

|

WB-ADH40

|

WB-ADH50

|

WB-ADH60

|

WB-ADH80

|

WB-ADH100

|

|||||||||

|

Hydrogen Capacity (Nm³/h)

|

5

|

10

|

20

|

30

|

40

|

50

|

60

|

80

|

100

|

|||||||||

|

Rated Ammonia Comsumption (Kg/h)

|

2

|

4

|

8

|

12

|

16

|

20

|

24

|

32

|

40

|

|||||||||

|

Rated Heating Power of Generator (KW)

|

6

|

12

|

29

|

39

|

50

|

62

|

75

|

100

|

125

|

|||||||||

|

Rated Heating Power of Purifier (KW)

|

2

|

4

|

5

|

8

|

10

|

12

|

15

|

18

|

20

|

|||||||||

|

Rated Furnace Temperature of Generator (℃)

|

≤800

|

|

|

|

|

|

|

|

|

|||||||||

|

Recycling Heating Temperature of Purifier (℃)

|

250

|

|

|

|

|

|

|

|

|

|||||||||

|

Rated Power Voltage (V)

|

380

|

|

|

|

|

|

|

|

|

|||||||||

|

Dew Point of Gas Purifier (℃)

|

≤-60

|

|

|

|

|

|

|

|

|

|||||||||

|

Remnant Ammonia Content of Gas Purifed (PPM)

|

≤10

|

|

|

|

|

|

|

|

|

|||||||||

Technological Process

Detailed Photos

Project Case

Product Application

Relative Products

Hydrogen Refueling Station

Fuel Cell Vehicle Hydrogenation Station

On-board Hydrogen Supply System

Liquid Hydrogen Storage & Transport Tanks

Hydrogen Gas Cylinder

Hydrogen Liquefaction Plant

Hydrogen Purification Equipment

Hydrogen Recovery Plant

Hydrogen drying equipment

Hot Searches