- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≤0.2%

-

Voltage:

-

220v,380v, or base on customer's requirements

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

NewWay

-

Dimension(L*W*H):

-

3400x1950x1900mm

-

Weight:

-

4000 KG

-

Product name:

-

beer can filling and seaming machine

-

Material:

-

304/316 Stainless Steel

-

Filling head:

-

20 Heads

-

Sealing head:

-

4 Heads

-

Filling material:

-

beer, gas-containing beverage

-

Production capacity:

-

30-150cans/min

-

After Warranty Service:

-

Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Online support

-

Certification:

-

CE

Quick Details

-

Machinery Capacity:

-

20000BPH

-

Packaging Material:

-

Plastic, Metal, Glass, tin/aluminum

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice, Carbonated drink

-

Filling Accuracy:

-

≤0.2%

-

Voltage:

-

220v,380v, or base on customer's requirements

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

NewWay

-

Dimension(L*W*H):

-

3400x1950x1900mm

-

Weight:

-

4000 KG

-

Product name:

-

beer can filling and seaming machine

-

Material:

-

304/316 Stainless Steel

-

Filling head:

-

20 Heads

-

Sealing head:

-

4 Heads

-

Filling material:

-

beer, gas-containing beverage

-

Production capacity:

-

30-150cans/min

-

After Warranty Service:

-

Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Online support

-

Certification:

-

CE

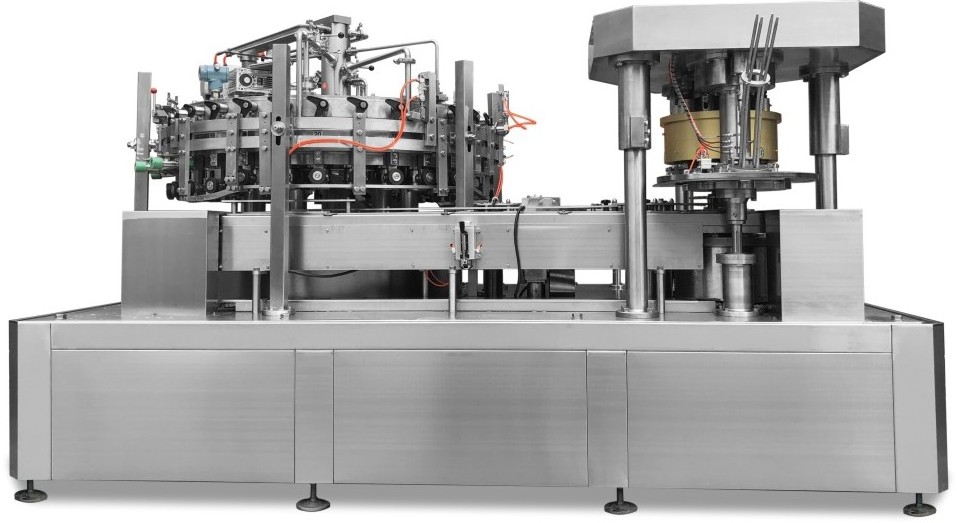

Product Description

The machine is suitable for filling and sealing of gas-containing beverages (carbonated drink beer and beverage) in the industrial of pop can beverage field. The filling and sealing are of integral design. It adopts the equal pressure filling principle.

The machine has such prominent features as high filling and sealing speed, consistent height from the liquid level in the can to the can mouth after filling, stable machine operation, good sealing quality, beautiful and decent appearance, convenient use and maintenance, touch screen operation, frequency conversion speed regulation, etc.

The machine has such prominent features as high filling and sealing speed, consistent height from the liquid level in the can to the can mouth after filling, stable machine operation, good sealing quality, beautiful and decent appearance, convenient use and maintenance, touch screen operation, frequency conversion speed regulation, etc.

Functional characteristics

The machine adopts PLC, frequency converter and man-machine interface control system. It has advanced control technology such as frequency conversion speed regulation, automatic filling with cans, no cans and no filling. Through various sensors on the device, the accurate production speed and quantity can be displayed

on the touch screen. The overall production speed can be set freely on the touch screen according to requirements. The whole machine has various protections of main motor and other electrical appliances, such as overload, overvoltage, etc.. At the same time, the corresponding faults will be automatically displayed on the touch screen to facilitate users to find out the causes of the faults. The main electrical components of this machine adopt internationally renowned brands, and can also be formulated according to customers’ requirements.

The whole machine is made of stainless steel plate and frame, which has good waterproof and rustproof functions.

The whole machine is made of stainless steel plate and frame, which has good waterproof and rustproof functions.

Size Information

Main technical parameters

|

Model

|

XW20-4Q

|

|

The number of sealing head

|

4

|

|

The number of filling head

|

20

|

|

Production capacity

|

30-150cans/min

|

|

Can diameter

|

Φ65mm

|

|

Can height

|

122-160mm

|

|

Power

|

7.5kw

|

|

Weight

|

4000kg

|

|

Dimension

|

3400*1950*1900mm

|

Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Sample testing support.

* View our Factory.

After-Sales Service

* Engineers available to service machinery overseas.

* Field installation, commissioning and training.

* Field maintenance and repair service.

* Field installation, commissioning and training.

* Field maintenance and repair service.

Company Introduction

Zhejiang NewWay Food Machinery Co., Ltd. is located in Zhoushan, the Oriental Pearl City Thousand Island City. It is 16 kilometers away from Mount Putuo airport. There are multiple flights to and fro Shanghai international airport everyday, 98 kilometers away from Ningbo Lishe airport, the traffic is very convenient.

The company is mainly engaged in the design and manufacture of beverages, canning machine and sealing machine packed with tinplate, aluminum, plastic and paper materials, as well as related products. Undertake the whole production line of easy-to-open beverage (including steam, non steam), sauce filling and sealing production line, Babao porridge canning, food, fruit and vegetable canning production line, etc.

The company fully uses CAD and CAM to design products. It is in a leading position in the field of filling and sealing equipment for canned food and beverage in China. The company specializes in the production of high-speed canning filling and sealing units and production lines, which make due contributions to the localization of similar imported equipment, reduce investment costs in the food and beverage industry, improve labor productivity of enterprises, and promote the rapid development and growth of the industry.

The company relies on strong technical force and effective technical guarantee, flexible business philosophy and quality service, advanced manufacturing technology, excellence in product quality and good reputation, to serve the vast number of new and old customers and welcome friends from all walks of life to visit and patronize.

The company is mainly engaged in the design and manufacture of beverages, canning machine and sealing machine packed with tinplate, aluminum, plastic and paper materials, as well as related products. Undertake the whole production line of easy-to-open beverage (including steam, non steam), sauce filling and sealing production line, Babao porridge canning, food, fruit and vegetable canning production line, etc.

The company fully uses CAD and CAM to design products. It is in a leading position in the field of filling and sealing equipment for canned food and beverage in China. The company specializes in the production of high-speed canning filling and sealing units and production lines, which make due contributions to the localization of similar imported equipment, reduce investment costs in the food and beverage industry, improve labor productivity of enterprises, and promote the rapid development and growth of the industry.

The company relies on strong technical force and effective technical guarantee, flexible business philosophy and quality service, advanced manufacturing technology, excellence in product quality and good reputation, to serve the vast number of new and old customers and welcome friends from all walks of life to visit and patronize.

Hot Searches