- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

1000/2000/3000/4000/5000/6000/7000 Series

-

Application:

-

According to customer requirements

-

Width:

-

C

-

Delivery Time:

-

7-30 days

-

Product Name:

-

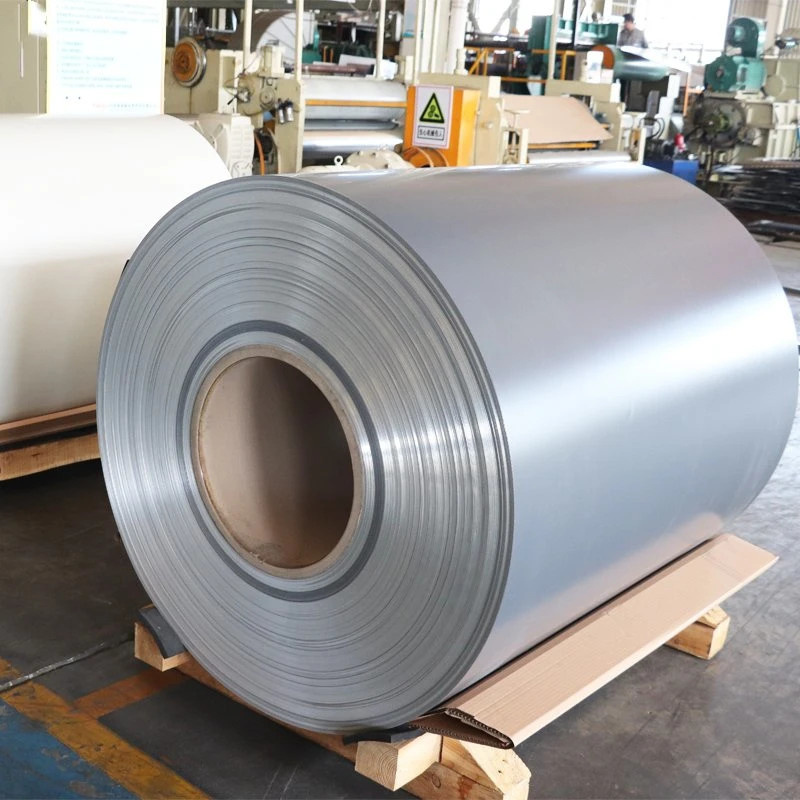

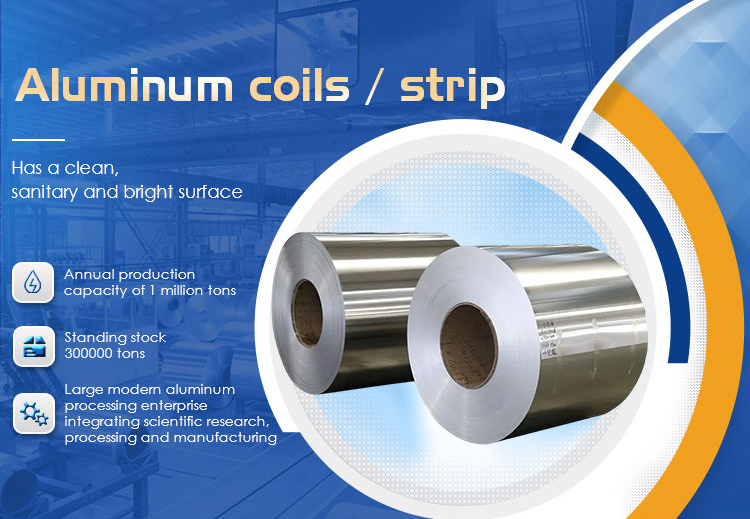

Aluminium coil

-

Keyword:

-

Aluminium coil

-

Shape:

-

Coil /strip

-

Standard:

-

ASTM AISI JIS DIN GB

-

Material:

-

Aluminum Material

-

MOQ:

-

5 Ton

-

Usage:

-

Construction Industry Decoration

-

Sample:

-

Provided Freely Sample

-

Packing:

-

International Standard Seaworthy Packing

Quick Details

-

Grade:

-

1000 Series,2000 series, 3000, seirs,

-

Tolerance:

-

±0.1%

-

Place of Origin:

-

China

-

Model Number:

-

1000/2000/3000/4000/5000/6000/7000 Series

-

Application:

-

According to customer requirements

-

Width:

-

C

-

Delivery Time:

-

7-30 days

-

Product Name:

-

Aluminium coil

-

Keyword:

-

Aluminium coil

-

Shape:

-

Coil /strip

-

Standard:

-

ASTM AISI JIS DIN GB

-

Material:

-

Aluminum Material

-

MOQ:

-

5 Ton

-

Usage:

-

Construction Industry Decoration

-

Sample:

-

Provided Freely Sample

-

Packing:

-

International Standard Seaworthy Packing

Products Description

When purchasing aluminum coils, you need to consider the following factors:

Purpose:

It is necessary to clarify the purpose of the aluminum coil, which field it is used in construction, transportation, home appliances, electronics, etc. Aluminum coils in different fields have different performance requirements, and it is necessary to choose the appropriate aluminum coil material and condition.

Material:

The main materials of aluminum coils are pure aluminum and alloy aluminum. Pure aluminum coils have good electrical and thermal conductivity, but low strength; alloy aluminum coils have high strength, but poor electrical and thermal conductivity. It is necessary to choose the appropriate material according to the usage requirements.

State:

The states of aluminum coils mainly include O state, H state, T state, etc. O-state aluminum coils have the best plasticity, but lower strength; H-state aluminum coils have higher strength, but poorer plasticity; T-state aluminum coils have strength and plasticity between the O-state and H-state. It is necessary to select the appropriate state according to the usage requirements.

Thickness:

The thickness of aluminum coils is generally between 0.2mm~6.0mm. It is necessary to choose the appropriate thickness according to the usage requirements.

Width:

The width of aluminum coils is generally between 100mm~2000mm. It is necessary to choose the appropriate width according to the usage requirements.

Surface quality:

The surface quality of the aluminum coil should be smooth and flat, without defects such as cracks and scratches.

Price:

The price of aluminum coils is affected by factors such as material, condition, thickness, and width. You need to choose the right price according to your budget.

Specification

|

Product name

|

Aluminum coil/strip

|

|

Aluminum alloy

|

1100 1060 1050 3003 3004 3005 3104 3A21 5052 5754 5083 5005 5A05 6061 6063 7075

|

|

Temper

|

F,O,T,W,Y,H12,H14,H16,H18,H19,H22,H24,H26,H28,H32,H34,H38,H112,H114

|

|

Thickness(mm)

|

0.2-8

|

|

Width (mm)

|

100-2650

|

|

Length(mm)

|

C

|

|

Applications

|

High-speed rail sound insulation barriers, tank truck body materials, high-grade alloy doors and windows, etc.lamp base materials, blind materials, heat sinks, LCD back sheet materials, aluminum substrates for color coating, etc.

|

|

Standard

|

GB/T 3880-2006 ,ASTM B209 ,EN 573-3,JIS H4000

|

|

delivery time

|

7-15 days

|

|

Surface treatment

|

mill finish, sandblasting, anodizing, electrophoresis, polishing, power coating

|

|

Payment terms

|

30% deposit, 70% balance before shipping by T/T; L/C at sight

|

|

Standard

|

Description

|

Application

|

Feature

|

|

1000 Series |

1050 1060 1070 1100 1235 representative series aluminum plate is also known as pure aluminum, in the series in 1000 series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above.

|

Utensil, decoration, Reflecting plate,

printing plate, heatproof plate, cookware |

Easy to process and weld, resistant to rust, high, conductibility of electricity and heat,low strength

|

|

3000 series |

3000 series aluminum represents 3003 3004,3005, 3A21 primarily. And can be called in the 3000 series aluminum antirust aluminum production process more outstanding. The 3000 series aluminum plate is by manganese as the main component. Content at 1.0-1.5

between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment |

Utensil(F/P, inside of rice cooker),

aluminum can,material for interior and exterior of building,chemical equipment,Cellular Phone |

20% higher strength than

the 1100 series, easily welded and brazed, good antirust,ability Non-heat treatable |

|

5000 series |

5000 series representatives 5052 5005 5083,5754. The 5000 series aluminum alloy aluminum belong to the more commonly used series, the main elements for magnesium, with magnesium in the amount between 3-5%. And can be called aluminum magnesium alloy. Key features for low density, high tensile strength, elongation rate is high. In the same area under the weight of the magnesium alloy aluminum less than other series.

|

Ship board heatproof apparatus,

material for interior and exterior of building, Parts of Electronic tools. Automobile Components |

Excellent corrosion resistance andweld ability together with Easy to process and weld and superior hardness &heatproof

Can be anodized for increased corrosion resistance |

|

6000 series |

6000 series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications.

|

IT equipment & facility,

Mould material, motor material, automatic line, machine & plant etc |

Easy to process , good corrosion resistance, high toughness and processed without distortion after heat-treatable, superior

surface treatment |

|

7000 series |

7000 aluminum alloy is another common alloy, wide variety. It contains zinc and magnesium. The best strength in the common aluminum alloy is 7075 alloy, but it can't be welded, and its corrosion resistance is rather poor, many manufacturing parts with CNC cutting is 7075 alloy.

|

The aerospace industry & High strength accessories

|

7000 series is high tensile to process

|

|

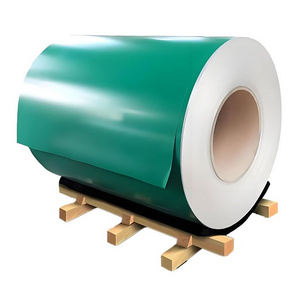

Coated aluminum coil

|

Coated aluminum coil is an aluminum coil that is coated with a layer of other metals or coatings on the surface of the aluminum coil to improve its corrosion resistance, decoration or other properties.

|

Coated aluminum coils are widely used in construction, transportation, home appliances, electronics and other fields.

|

Corrosion resistance: The coating protects the aluminum coil from corrosion and extends its service life.

Decorative: The coating can be provided in a variety of colors and patterns to meet different decorative needs. Other properties: Coating can improve the wear resistance, electrical conductivity, thermal conductivity and other properties of aluminum coils.

|

|

Composite aluminum coil

|

Composite aluminum coil is an aluminum coil composed of two or more layers of aluminum coils.

|

Composite aluminum coils are widely used in construction, aerospace, packaging and other fields.

|

High strength: Composite aluminum coils are stronger than single-layer aluminum coils and can withstand greater loads. Highstiffness: The stiffness of composite aluminum coils is higher than that of single-layer aluminum coils and is not easy to deform.

Good barrier properties: Composite aluminum coils can block gas, liquid and light, and have good sealing and light-shielding properties. |

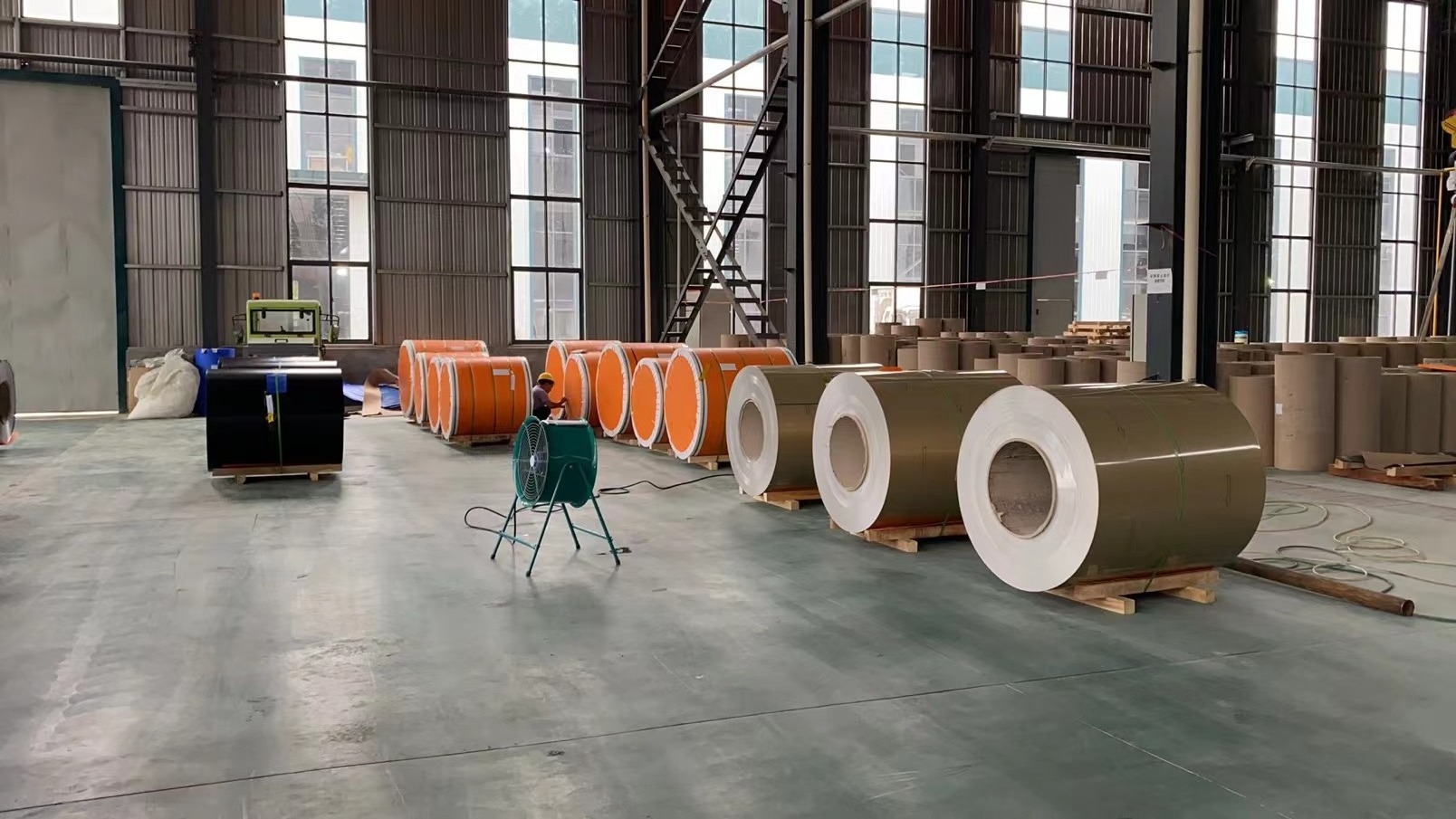

Product display

Packing and Shipping

Hot Searches