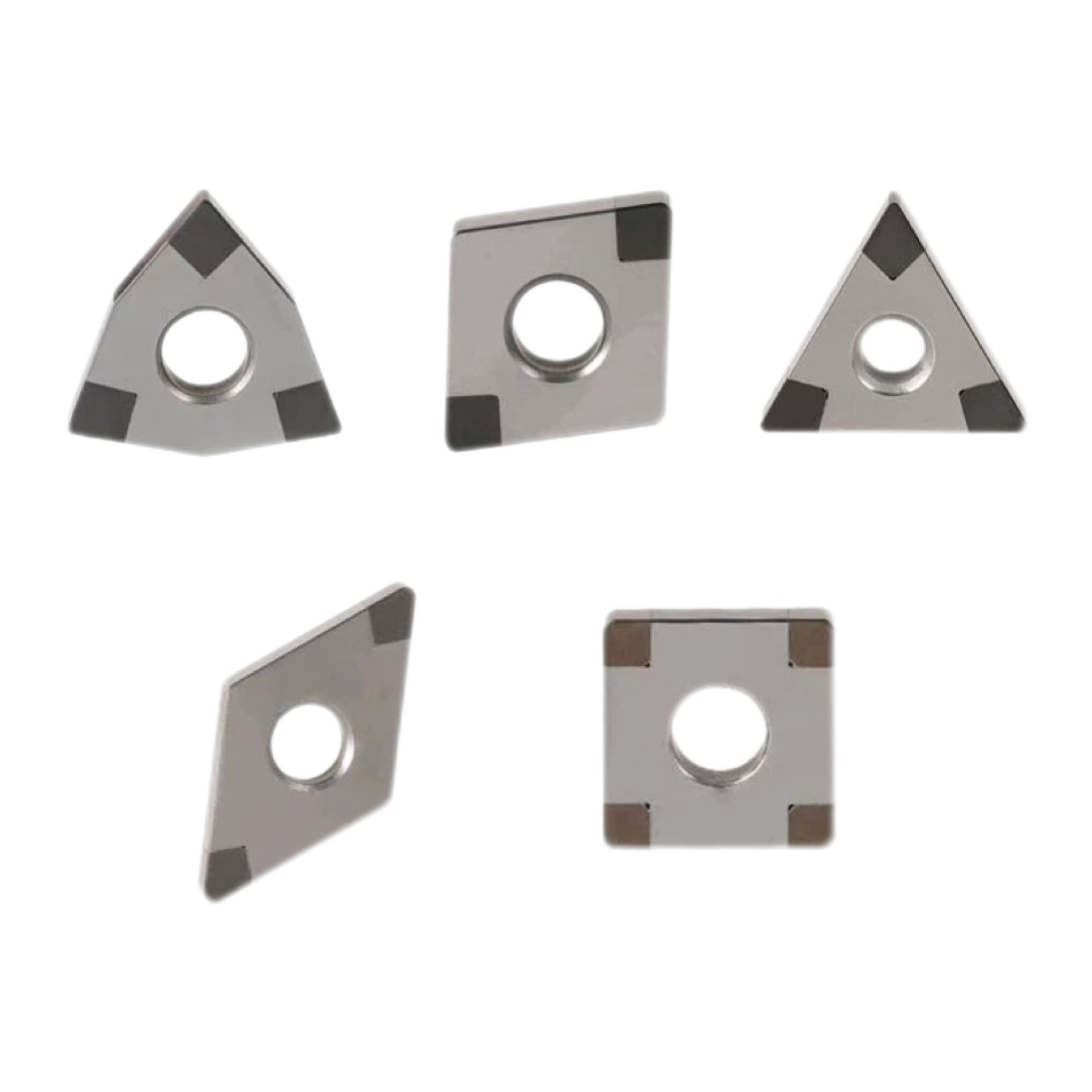

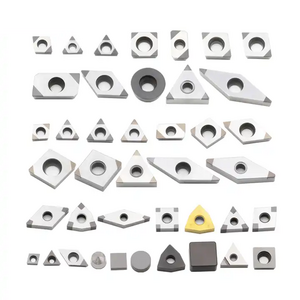

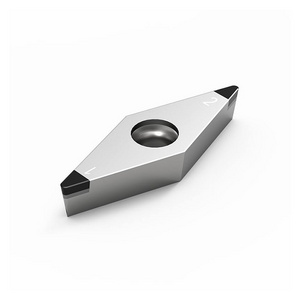

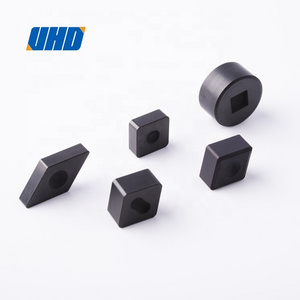

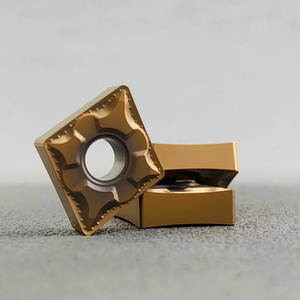

The main business of our company is metal cutting as the core, and at the same time, we have diversified businesses such as sales of metal tools, sales of machine tool functional parts and accessories, and research and development of metal cutting tools. We are committed to providing customers with efficient, accurate and reliable metal cutting solutions to help customers improve production efficiency and product quality.

We are a professional team service system, contact us for your needs!