- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

5000 kg

-

Product Name:

-

Organic waste gas direct-fired oxidizer

-

Application:

-

Exhaust gas treatment furnace

-

Feature:

-

High purification rate

-

Usage:

-

Industrial waste gas purification

-

Product type:

-

Industrial purifiers

-

Color:

-

Customers' Requirements

-

Function:

-

Industrial waste gas treatment

-

Size:

-

Customized

-

Certification:

-

ISO9001:2008

-

After-sales Service Provided:

-

Online Support

Quick Details

-

Marketing Type:

-

Hot Product 2024

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

YU YOU

-

Weight (KG):

-

5000 kg

-

Product Name:

-

Organic waste gas direct-fired oxidizer

-

Application:

-

Exhaust gas treatment furnace

-

Feature:

-

High purification rate

-

Usage:

-

Industrial waste gas purification

-

Product type:

-

Industrial purifiers

-

Color:

-

Customers' Requirements

-

Function:

-

Industrial waste gas treatment

-

Size:

-

Customized

-

Certification:

-

ISO9001:2008

-

After-sales Service Provided:

-

Online Support

PRODUCT DESCRIPTION

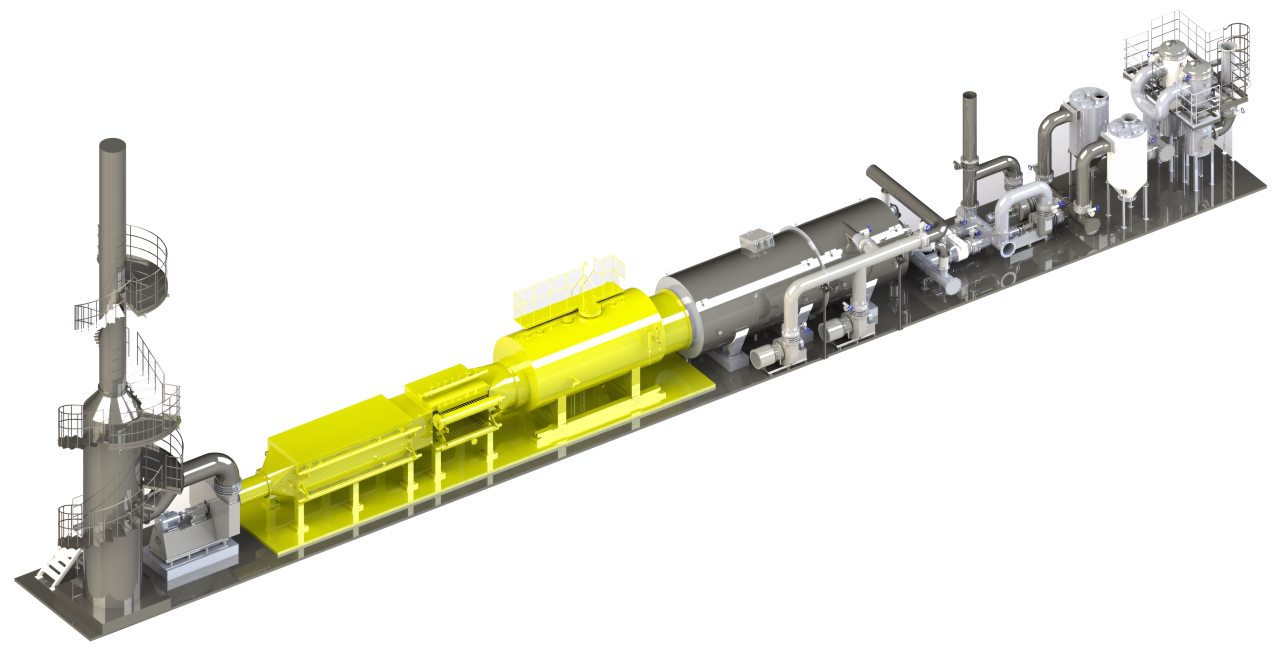

Introduction of

Organic waste gas direct combustion oxidiser

:

TO is a high-temperature oxidation system that directly sprays composite exhaust gas or organic gas, white smoke, odor, haze and other exhaust gases into a direct-fire combustion chamber, so that the exhaust gases come into direct contact with the high-temperature flame for oxidative decomposition.

In general, the treatment temperature is set according to the ignition point (700 degrees ~ 900 degrees Celsius) of the composition of the gas to be treated, and it stays in the combustion chamber for 0.7~1.5 seconds for exothermic reaction treatment.

When all three conditions of incineration, temperature, residence time, and mixing, are satisfied, the optimum treatment effect is obtained.

The technology is characterized by an efficiency of more than 99% in the treatment of exhaust gases. In order to save high energy costs, the preheat exchanger should reduce energy by recovering heat, minimizing the fuel consumption of the system.

And it is very effective in small and medium sized industrial sectors and has very compact dimensions.

-Small size of the device;

-Low input cost of the device;

-Can add waste heat boiler for waste heat recovery;

-Automatic control, simple operation.

Product Features

:

Our business scope

:

Complete furnace design, supply of complete sets/partial parts(Metallurgical Equipment:Electric arc furnace (EAF), ladle refining furnace (LF), vacuum refining furnace (VD/VOD), submerged arc furnace (SAF).

Spare Parts:Transformer, water cooled compensator, short net busbar, water cooled cable, electrode conductive arm, forged electrode contact pad, forged copper tile, water cooled roof, water cooled upper shell, water cooled panel, water cooled fume duct, water cooled fume hood, etc.), retrofitting services, induction/maintenance training, technical consulting.

Spare Parts:Transformer, water cooled compensator, short net busbar, water cooled cable, electrode conductive arm, forged electrode contact pad, forged copper tile, water cooled roof, water cooled upper shell, water cooled panel, water cooled fume duct, water cooled fume hood, etc.), retrofitting services, induction/maintenance training, technical consulting.

PRODUCT PARAMENTERS

|

Areas of application

|

Main target substances

|

|

Coatings industry

|

Toluene, xylene, isopropyl alcohol, methanol, butanone, butynol esters

|

|

Painting industry

|

Toluene, isopropanol, butanone, hexane

|

|

Chemical industry

|

Aldehydes, ketones, ethylene, carbon monoxide, acrylic acid

|

|

Cable manufacturing

|

Benzene, toluene, butynol esters

|

|

Metal casting industry

|

Carbonic acid, formaldehyde

|

|

Food processing industries

|

Fatty acids, alcohol

|

|

Fatty acids, mercaptans

|

Toluene, isocyanic acid, rubber odor

|

PRODUCT PACKAGING

★

Our packaging advantages:

1. Security guarantee:

For special commodities such as easily damaged items, the packaging design is more rigorous, using shockproof, leakproof and other strategies to reduce the probability of damage. At the same time, in the choice of packaging materials, the selection of high-strength materials, such as foam tin boxes, bubble bags wooden boxes, etc., in order to ensure that the goods are not damaged in transportation.

2. Size rationalization:

The cost of express delivery is closely related to the size, too large packaging will cause a waste of freight, too small packaging may lead to damage to the goods in transit. Therefore, through the accurate measurement of the size and weight of the goods, we reasonably select the packaging capacity and use adjustable packaging materials, which can better meet the needs of commodity transportation and save transportation costs at the same time.

3. Environmentally friendly:

With the global awareness of environmental protection, environmentally friendly packaging is gradually becoming a trend in the industry. We choose recyclable and biodegradable materials and avoid using too much plastic packaging. Reasonable use of space to achieve the purpose of saving resources.

4. Fast and convenient:

We have very professional and practicing for many years of foreign trade logistics personnel, to ensure that customers can receive products in a timely and rapid manner. At the same time, we are also optimizing the after-sales service, the use of easy to unpack, loading and unloading, convenient for customers to check the packaging of goods. We believe that reasonable packaging design can provide better transportation security for enterprises and enhance brand value.

SALES AND SERVICE NETWORK

OUR PATENTS & CERTIFICATIONS

COMPANY PROFILE

Deeply appreciate your enquiry, our factory in Yixing, China has more than 30 years of production experience, hundreds of employees and ten million dollars turnover. Your inquiry and visit are always welcome.

Main products: water-cooled cables,water-cooled compensators, forged copper tiles, forged/cast bottom rings, electrode holders, short copper pipe grids, water-cooledfurnace covers, pressure rings, hydraulic holding gates, conductive cross-arms and so on.

Hot Searches