- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

cnc machining1

-

Product Name:

-

plastic mould for auto parts

-

Mould material:

-

P20/718/738/NAK80/S136

-

Surface treatment:

-

Polishing

-

Mould Life:

-

250000-300000shots

-

Cavity:

-

Single Cavity\ Multiple Cavity

-

Plastic material:

-

ABS/PP/PS/PE/PVC/PA6/PA66/PMMA

-

Runner:

-

Hot Runner\ Cold Runner

-

Design software:

-

PDF ,IGS ,STEP

-

Keyword:

-

Plastic Parts Customize

-

Surface Finishing:

-

EDM Finish

Quick Details

-

Shaping Mode:

-

plastic injection mold / mould making china manufacturer

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

cnc machining

-

Model Number:

-

cnc machining1

-

Product Name:

-

plastic mould for auto parts

-

Mould material:

-

P20/718/738/NAK80/S136

-

Surface treatment:

-

Polishing

-

Mould Life:

-

250000-300000shots

-

Cavity:

-

Single Cavity\ Multiple Cavity

-

Plastic material:

-

ABS/PP/PS/PE/PVC/PA6/PA66/PMMA

-

Runner:

-

Hot Runner\ Cold Runner

-

Design software:

-

PDF ,IGS ,STEP

-

Keyword:

-

Plastic Parts Customize

-

Surface Finishing:

-

EDM Finish

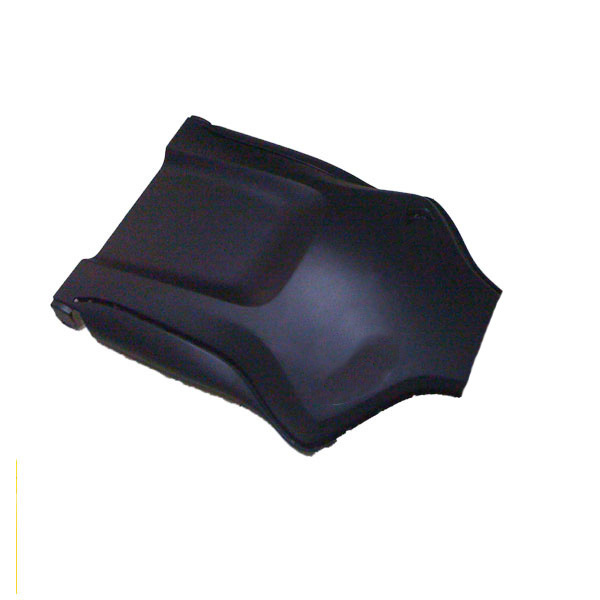

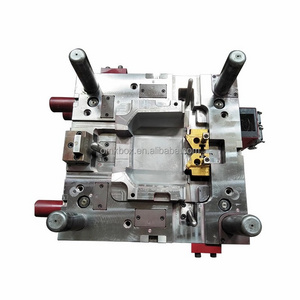

Customized Car Parts Plastic Injection Moulding Process For Auto Airbag Cover Mould

|

Mold Base: |

LKM,HASCO,DME,etc... |

|

Product Name: |

PVC UPVC resin mold inserts injection mould design/resin molds for Business Machine Parts |

|

Mold Cavity: |

Single, Mult, Family... |

|

Molding Material: |

ABS, PA6, PA12,PA66, PBT, PC,PC/ABS,PC/PBT,PE-HD,PE-LD,PEI,PET,PETG,PMMA,POM,PP,PPE,PS,PVC,SA... |

|

Color: |

transparent, solid color according to your requests |

|

Surface: |

textured,glossy or mirror polished,printing,plantingect. |

|

Design software: |

PRO/E.Solidwork,UG.Moldflow.Autocad,etc |

|

Mold Material: |

S45C, P20, 718, 718H, 2738, 738H, NAK80, SKD61, E420, etc. (for reference only) |

|

File Formats |

Autodesk Inventor, SolidWorks, CATIA V5, Solid Edge, UGS NX, Pro/ENGINEER STEP, IGES, SAT, DWG, DXF, VDA. |

|

Mold Life: |

300,000~1,000,000cyces according to your requests |

|

Runner: |

Cold, hot runner such as YUDO.MASTER.SYNVENTIVE.etc. |

|

Lead time to T1 sample: |

3~5 weeks |

|

lead-time for production: |

1~2 weeks |

|

Quality: |

ISO 9001:2000 |

|

Precision: |

0.005mm |

|

Service: |

OEM &ODM service. and mold for exports as well. |

| Injection molding | Die Casting | Investmentcasting |

| Mould material:P20/718/738/NAK80/S136 | Mould material:P20/718/738/H13/8407/SKD | Material: Stainless Steel/carbon steel |

| Plastic material:ABS/PP/PS/PE/PVC/PA6 | ALU material: Aluminum:ADC12,ADC10, | Mould material:P20/718/738 |

| Dimension: Customized | A360,A356,A380,A413,B390,EN47100 |

Standards:AISI,ASTM,DIN,EN, JIS,GB,etc. |

| Runner:Hot Runner\ Cold Runner | Dimensions: Customized Sizes | Dimensions: Customized Sizes |

| Toling | Mass Production | more product |

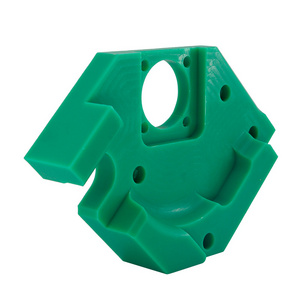

| Product: Customized plastic mould&mold | Material: ABS,PA,POM,PE,PP,PS,PMMA,etc | Customized |

| Surface treatment: Polish, Etched,Texture |

Quality Control: ISO/TS16949:2002 and ISO14001:2004 system |

|

|

Gate type: Point gate,Edge gate,Sub gate in part,Fan gate |

Surface Finish: polished,powder coating,chrome, etc. |

1,ISO9001: 2008 Authentication

2,Over 18 years in precision plastic mould manufactring with extensive experience

3,Best Price: Real direct factory and manufacturer without third party

4,OEM, Trial order and sample order are acceptable

5,Professional Teams and Employees who are specialized in mould design and manufacturing.

6,Reasonable and competitive price

7,Fast delivery

We adhere to the business philosophy of “professional mold design, precision mold manufacturing, strict quality control and honest operation approach”. We promise to provide our clients with “the best quality, the most competitive price and prompt delivery”