- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

30 rpm

-

Place of Origin:

-

China

-

Brand Name:

-

WingsPlastic

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

8000mm 2000mm 2500mm

-

Power (kW):

-

40

-

Weight:

-

3000 KG

-

Motor:

-

China Top Brand

-

Inverter:

-

Delta Brand

-

Temperature controller:

-

Omron Brand

-

Contactor:

-

Siemens Contactor

-

switch:

-

CHNT

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Output:

-

200 - 250 Kg/h

-

Final product:

-

high speed single wall corrugated pipe

-

Raw material:

-

PP PE pvc hdpe

-

Automatic Grade:

-

High Automation

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw diameter (mm):

-

45 mm

-

Screw Speed (rpm):

-

30 rpm

-

Place of Origin:

-

China

-

Brand Name:

-

WingsPlastic

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

8000mm 2000mm 2500mm

-

Power (kW):

-

40

-

Weight:

-

3000 KG

-

Motor:

-

China Top Brand

-

Inverter:

-

Delta Brand

-

Temperature controller:

-

Omron Brand

-

Contactor:

-

Siemens Contactor

-

switch:

-

CHNT

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Output:

-

200 - 250 Kg/h

-

Final product:

-

high speed single wall corrugated pipe

-

Raw material:

-

PP PE pvc hdpe

-

Automatic Grade:

-

High Automation

Final Product & Application

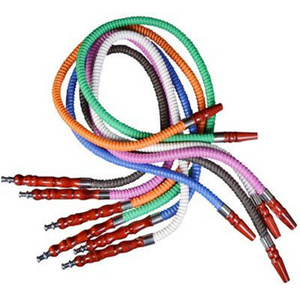

Applications Of Shisha Pipes:

Plastic hookah/shisha hose making machine

Application: Shisha pipe/hook pipe, electric pipe etc, water drain pipe etc.

Raw material: PVC granule, PE/PP granule, PA granule.

Diameter: 10-55 mm

Capacity: 20-50 kg/h

Model: Normal speed and high speed

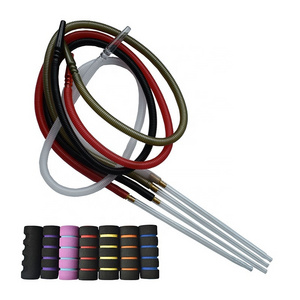

Plastic hookah/shisha hose making machine

Application: Shisha pipe/hook pipe, electric pipe etc, water drain pipe etc.

Raw material: PVC granule, PE/PP granule, PA granule.

Diameter: 10-55 mm

Capacity: 20-50 kg/h

Model: Normal speed and high speed

Product Description

Hookah Shisha Pipes Machine Plastic Corrugated Pipe Disposable Hookah Hose Hookah Making Machine For Water Smoking Hose

Hookah Pipe Making Machine

,

Plastic Shisha Corrugated Pipe Machine,

Hookah Hose

PP PVC PE Shisha Corrugated Pipe Production Line Advantage.

Whole line consists of Single Screw Extruder, Mould, Forming Machine(With Corrugated Forming Pairs), Auto-Tension Controller, and Winder Unit. It adopts gear transmission module and cooling water circulation for cooling, which production speed can be up to 10-15m/min, and the pipe with characteristics of one-step forming, uniform shape of the ripples, consistent joint, smooth inside and outside pipe wall.

Whole line consists of Single Screw Extruder, Mould, Forming Machine(With Corrugated Forming Pairs), Auto-Tension Controller, and Winder Unit. It adopts gear transmission module and cooling water circulation for cooling, which production speed can be up to 10-15m/min, and the pipe with characteristics of one-step forming, uniform shape of the ripples, consistent joint, smooth inside and outside pipe wall.

Structure design of special screw and mould is reasonable, replacement of mould is convenient and reliable, and the problem of easy wear of screw barrel and difficult forming of material is solved. The production line has fast and stable speed, easy to operate.

Single Screw Extruder

High production capacity of extrusion on the high quality basis. Lower temperature plasticizing design, ensure high quality PIPE

extrusion. Material of screw and barrel: 38CrMoAlA, nitrogen quenched (0.4-0.7mm ), Rigidity of screw: >740 , Rigidity of barel

>940, the surface of screw is chromeplated Feeding bush with water cooling system

extrusion. Material of screw and barrel: 38CrMoAlA, nitrogen quenched (0.4-0.7mm ), Rigidity of screw: >740 , Rigidity of barel

>940, the surface of screw is chromeplated Feeding bush with water cooling system

Extrusion Die

Material :40Cr , the surface of die is chromeplated, anti-corrosive

core bar and mouth mould

new design,the

core bar and mouth mould

fit together,when change size,no like the old design change the core bar and mouthe separately,it will be save more than 1h for the clean the waste material.

High Speed Forming Machine

Gear driven system with high precision modules and tracks. The track is water cooling system, it could meets 10-30m/min working speed.It is added water cooling and fan cooling two system.

wear resistance and fatigue strength,and has good heat resistance and corrosion resistance,hardenability is not high,used for making nitriding parts with high wear resistance,high faigue strength,considerable strength and high diamensional precision after treatment

.the pipe inner side more smooth,increase the production speed and product quality.

Forming machine adjustment:manual control left and right,Electric control up and down.

Forming machine adjustment:manual control left and right,Electric control up and down.

Moulds Block

Materials of moulds block:40CrThe moulds are made by CNC system, it is high precison and long service life.

It could be designed into one hole or two hole according customer request.

We could print customers logo into moulds according request.

It could be designed into one hole or two hole according customer request.

We could print customers logo into moulds according request.

Automatic coiler

No of wheel: two wheel or one wheel according customer requestUseing delta inverter system, it is automatic adjustment of winding speed.

Control Box

Temperature controller: OMRON

Contactor and replay: SIEMENS

Inverter: ABB or Delta Character

High precise temperature control.

Configurable alarm strategy.

All of the production data can be displayed electrical panel.

Very easy operation.

Running stability

Model & Parameters

|

Extruder Model

|

SJ45

|

SJ65

|

|

Screw diameter (mm)

|

45

|

65

|

|

Ration of L/D

|

28-33:1

|

28-33:1

|

|

Pipe diameter range

|

9-32

|

32-110

|

|

Pairs of modules

|

42 (50)

|

50

|

|

Line speed (m/min)

|

3-15

|

3-15

|

|

Module cooling way

|

Air-cooled

|

Air-cooled

|

|

Pipe cooling way

|

Air-cooled

|

Air-cooled

|

|

Total install powder (kw)

|

50

|

70

|

Company Introduction

Qingdao Wings Plastic Technology Co., LTD., specializing in the production of HDPE PP PVC PA single wall corrugated pipe machine, double-wall corrugated pipe production line,

Equipment operation is stable, automatic production, saving labor, efficient extrusion

Equipment operation is stable, automatic production, saving labor, efficient extrusion

Corporate Power

With sophisticated Extruder production equipment,Fully Automatic PLC Control System and skilled workers, We can provide high quality machine in required time.

•Our Machine are highly approved by authority organization and our customers.

• We attend several exhibitions, and our products are popular in these exhibitions because of their good quality.

• Our Machine are sold to many areas such as: Eastern Europe, Centural America, South America, North America,Mid East,etc..

•Our Machine are highly approved by authority organization and our customers.

• We attend several exhibitions, and our products are popular in these exhibitions because of their good quality.

• Our Machine are sold to many areas such as: Eastern Europe, Centural America, South America, North America,Mid East,etc..

Our Service

After all machines are delivered to customer’s factory; Buyer is responsible for all preparation work, e.g. electricity supply,

water supply, labors and cranes, etc.

water supply, labors and cranes, etc.

- Wings will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer’s factory.

- The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD100 per day for each engineer.

- Engineer will give free training lessons to labors in buyer’s factory.

- If buyer doesn’t request installation and commissioning by Seller’s engineer in 4 months since date of bill of lading, which to be accounted all the machines has been successfully tested by buyer.

Recommend Products

Hot Searches