- Product Details

- {{item.text}}

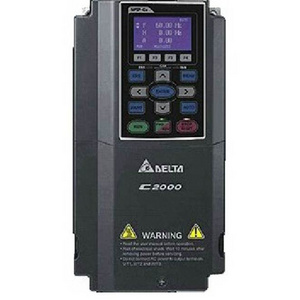

Quick Details

-

Model Number:

-

VFD002EL11A VFD002EL21A

-

Type:

-

Variable Frequency Drive inverter

-

Product name:

-

Variable Frequency Drive inverter

-

Application:

-

industrial automationindustrial automation industrial control

-

Product Type:

-

VFD-EL series small general non - sense vector frequency converter

-

item number:

-

VFD002EL11A VFD002EL21A

-

Input power supply (V):

-

115V/220V 1-Phase

-

Output current (A):

-

1.6

-

Maximum output frequency (Hz):

-

599

-

Motor power (kW):

-

0.2

-

control method:

-

IMVF ; IMSVC (Space Vector Control) ; PMSVC

-

protection class:

-

IP20

Quick Details

-

power phase number:

-

3

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Delta

-

Model Number:

-

VFD002EL11A VFD002EL21A

-

Type:

-

Variable Frequency Drive inverter

-

Product name:

-

Variable Frequency Drive inverter

-

Application:

-

industrial automationindustrial automation industrial control

-

Product Type:

-

VFD-EL series small general non - sense vector frequency converter

-

item number:

-

VFD002EL11A VFD002EL21A

-

Input power supply (V):

-

115V/220V 1-Phase

-

Output current (A):

-

1.6

-

Maximum output frequency (Hz):

-

599

-

Motor power (kW):

-

0.2

-

control method:

-

IMVF ; IMSVC (Space Vector Control) ; PMSVC

-

protection class:

-

IP20

Products Description

|

Product name

|

Variable Frequency Drive inverter

|

|

Application

|

industrial automation industrial control

|

|

Product Type

|

VFD-EL series small general non - sense vector frequency converter

|

|

item number

|

VFD002EL11A VFD002EL21A

|

|

Input power supply (V)

|

115V/220V 1-Phase

|

|

Output current (A)

|

1.6

|

|

Same series model

|

VFD002EL11A

VFD002EL21A VFD002EL23A VFD004EL11A VFD004EL21A VFD004EL23A VFD004EL43A VFD007EL11A VFD007EL21A VFD007EL23A VFD007EL43A VFD015EL21A VFD015EL23A VFD015EL43A VFD022EL21A VFD022EL23A VFD022EL43A VFD037EL23A |

|

Motor power (kW)

|

0.2

|

|

control method

|

IMVF ; IMSVC (Space Vector Control) ; PMSVC

|

|

protection class

|

IP20

|

|

Type of motor

|

Induction Motor(IM) ; Interior Permanent Magnet Motor(IPM) ; Surface Permanent Magnet Motor(SPM)

|

|

loadtype

|

Constant Torque ; Fan & Pump Application

|

|

Function

|

run an AC motor at variable speeds or let them ramp up their speed to give them a smooth startup

|

|

product feature

|

Easy to install

Side by side installation is allowed for through-wall installation and wall-mounted installation USS and MODBUS RTU communication terminals 7.5KW~30kw frequency converter integrated brake unit Comply with electromagnetic compatibility (EMC) class C1/C2 Easy to use No need to connect to the main power supply to send the implementation parameters loading Built-in application macro and connection macro The abnormal non-stop mode can achieve uninterrupted operation Mobile phones, tablets and other mobile devices can easily connect to V20 through wireless connection, and the debugging operation is intuitive and efficient Wide voltage range, advanced cooling design and coated PCB board are used to improve the stability of the inverter. Cost savings Basic mode for V/f, V2/F, sleep mode Support energy consumption and traffic monitoring Heavy load mode and light load mode for profile size E |

|

WHY SHOULD I USE A VFD?

|

Reduce Energy Consumption and Energy Costs If you have an application that does not need to be run at full speed, then you can cut

down energy costs by controlling the motor with a variable frequency drive, which is one of the benefits of Variable Frequency Drives. VFDs allow you to match the speed of the motor-driven equipment to the load requirement. There is no other method of AC electric motor control that allows you to accomplish this. Electric motor systems are responsible for more than 65% of the power consumption in industry today. Optimizing motor control systems by installing or upgrading to VFDs can reduce energy consumption in your facility by as much as 70%. Additionally, the utilization of VFDs improves product quality, and reduces production costs. Combining energy efficiency tax incentives, and utility rebates, returns on investment for VFD installations can be as little as 6 months. |

|

|

Increase Production Through Tighter Process Control By operating your motors at the most efficient speed for your application,

fewer mistakes will occur, and thus, production levels will increase, which earns your company higher revenues. On conveyors and belts you eliminate jerks on start-up allowing high through put. |

|

|

Extend Equipment Life and Reduce Maintenance Your equipment will last longer and will have less downtime due to maintenance when

it’s controlled by VFDs ensuring optimal motor application speed. Because of the VFDs optimal control of the motor’s frequency and voltage, the VFD will offer better protection for your motor from issues such as electro thermal overloads, phase protection, under voltage, overvoltage, etc.. When you start a load with a VFD you will not subject the motor or driven load to the “instant shock” of across the line starting, but can start smoothly, thereby eliminating belt, gear and bearing wear. It also is an excellent way to reduce and/or eliminate water hammer since we can have smooth acceleration and deceleration cycles. |

Shenzhen Muma Automation Techonology Co.,LTD.

We are a professional industrial 4.0 solution provider in Shenzhen, China. Focus on industrial automatic equipment provide and software combination. Our mission is making the modern industrial more intelligent, more efficiency. The mainly products including servo motor, servo motor driver, stepper close motor, gear-motor, vibration motor, brush-motor, brush-less motor, PLC (Programmable Logic Controller), HMI (Human-machine interaction), inverter much industrial automation equipment and all-in-one solution providing.

Hot Searches