- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

12 months

-

Brand Name:

-

First Pump

-

Model Number:

-

DQI

-

Place of Origin:

-

Beijing, China

-

Horsepower:

-

0.55-132 kw

-

Power Source:

-

Electric Motor / Diesel Engine

-

Outlet Size:

-

2-8 inch

-

Power:

-

0.55-132 kw

-

motor:

-

As customer request

-

Material:

-

Cast Iron/SS304/SS316/SS316L/duplex Stainless/SS904L

-

Shaft Seal:

-

Packing Seal/Mechanical Seal

-

Connection Type:

-

Belt/Direct Coupling

-

Driven:

-

Electric Motor, Diesel Engine

-

Feature:

-

Energy Saving

-

Color:

-

Blue Red Yellow Black

-

Function:

-

Water Drainage

-

Keywords:

-

Fire Pump System

-

Impeller:

-

Closed Impeller

-

OEM:

-

OEM Services Provided

Quick Details

-

Application:

-

Biofuel Industry, Developing World Water Solutions, HVAC OEM, Industrial Boilers, Industrial Utilities, Irrigation and Agriculture, Machining, Marine, Metal and Equipment Manufacturers, Mining industry, temperature control, wastewater treatment, Water Distribution

-

Pressure:

-

High pressure

-

Voltage:

-

220V/380V/440V/As customer request

-

Warranty:

-

12 months

-

Brand Name:

-

First Pump

-

Model Number:

-

DQI

-

Place of Origin:

-

Beijing, China

-

Horsepower:

-

0.55-132 kw

-

Power Source:

-

Electric Motor / Diesel Engine

-

Outlet Size:

-

2-8 inch

-

Power:

-

0.55-132 kw

-

motor:

-

As customer request

-

Material:

-

Cast Iron/SS304/SS316/SS316L/duplex Stainless/SS904L

-

Shaft Seal:

-

Packing Seal/Mechanical Seal

-

Connection Type:

-

Belt/Direct Coupling

-

Driven:

-

Electric Motor, Diesel Engine

-

Feature:

-

Energy Saving

-

Color:

-

Blue Red Yellow Black

-

Function:

-

Water Drainage

-

Keywords:

-

Fire Pump System

-

Impeller:

-

Closed Impeller

-

OEM:

-

OEM Services Provided

2-3 Cylinders Diesel Engine Driven Water Pump 350-500 GPM

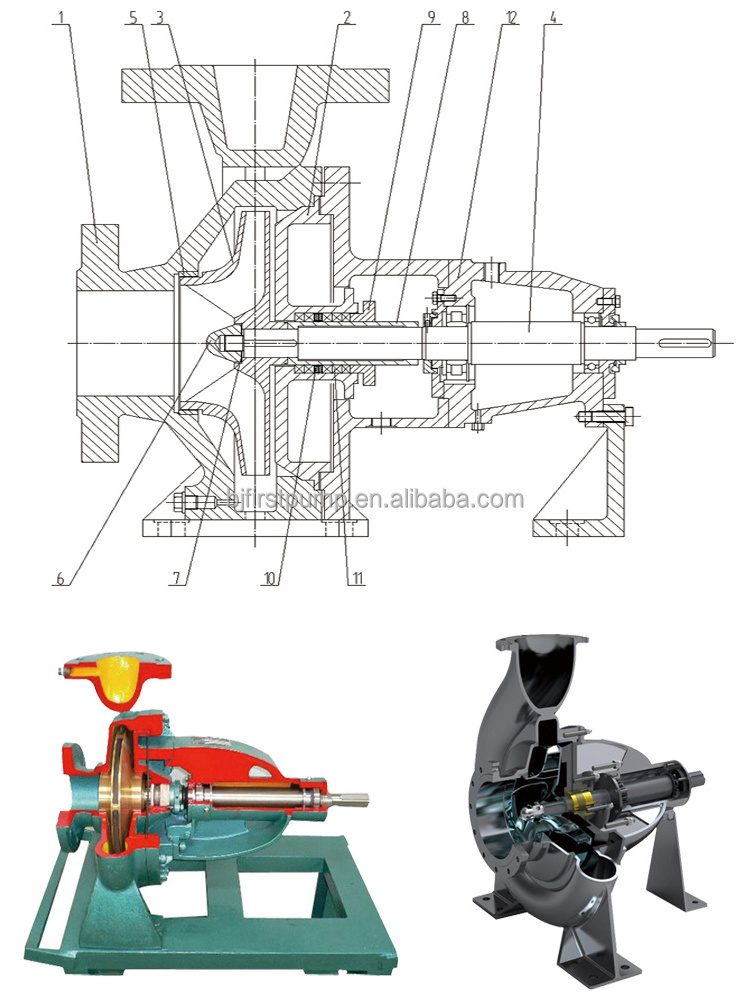

The ISO2858 international standard is met by the QI series single stage single suction centrifugal water pumps (end suction pumps).

The open back structure makes it simple to remove the rotor.

Discharge on top center, pump body supported by anchor ensure robust structure and maximum resistance to off-center and deformation induced by line stress.

Make sure there is no overload design and that the performance is stable.

Adopting a national standard hydraulic model ensures high operational efficiency and anti-cavitation performance.

Packing seals and mechanical seals are both available.

| Type | Flow | Head | Power |

| (m3/h) | (m) | (KW) | |

| QI50 | 3.4-15 | 3.7-68.8 | 0.55-11 |

| QI65 | 6.8-30 | 3.7-126.8 | 0.55-30 |

| QI80 | 13.6-60 | 3.6-128 | 0.55-45 |

| QI100 | 27.3-120 | 3.4-115.5 | 1.5-75 |

| QI125 | 56-240 | 8.5-132.5 | 2.2-110 |

| QI150 | 99-240 | 12.4-57.5 | 15-55 |

| QI200 | 197.7-460 | 14.8-55.8 | 30-90 |

| QI 250 | 320-760 | 22.6-52 | 75-132 |

| QI 300 | 530-1200 | 21.9-38 | 90-132 |