- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Bole Tech

-

Dimension(L*W*H):

-

994*994*1545mm

-

Weight:

-

230

-

Volume:

-

1200

-

Material:

-

SUS304/SUS316L

-

Thickness:

-

3mm

-

Discharge port:

-

DN250

-

Feeding port:

-

DN500

-

Function:

-

Storage, transferring

-

Application:

-

Nutriceutical, food chemical

-

Certificated:

-

CE

-

Standard:

-

GMP

-

Customized:

-

Yes

Quick Details

-

Capacity:

-

1200L

-

Max Working Pressure(MPa):

-

0.3 MPa

-

Core Components:

-

Valve, Vessel

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Bole Tech

-

Dimension(L*W*H):

-

994*994*1545mm

-

Weight:

-

230

-

Volume:

-

1200

-

Material:

-

SUS304/SUS316L

-

Thickness:

-

3mm

-

Discharge port:

-

DN250

-

Feeding port:

-

DN500

-

Function:

-

Storage, transferring

-

Application:

-

Nutriceutical, food chemical

-

Certificated:

-

CE

-

Standard:

-

GMP

-

Customized:

-

Yes

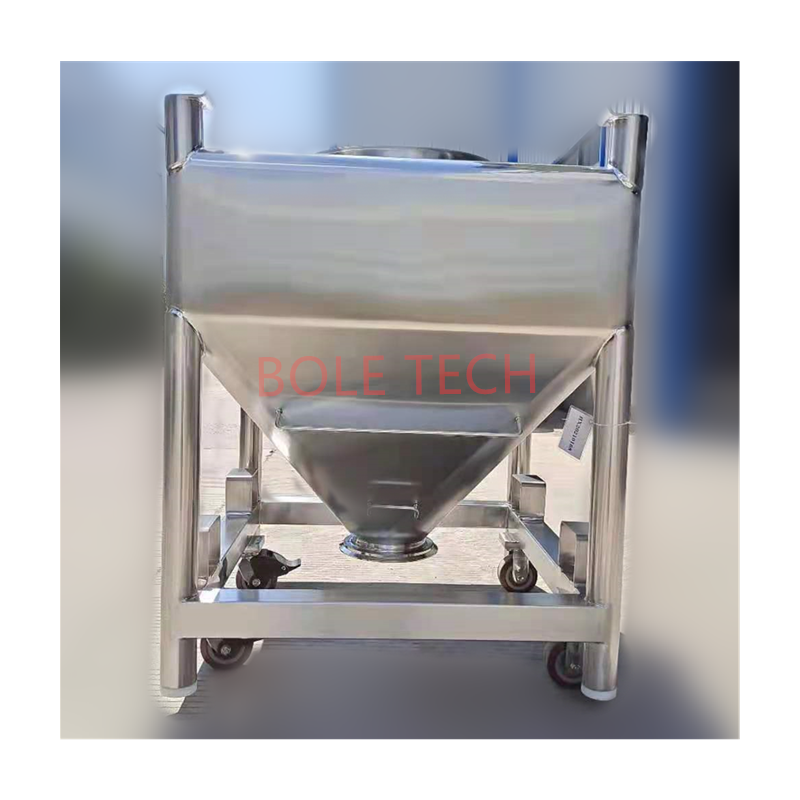

Products Description

This IBC tank is used for material transfer and storage in the production process of solid preparation. It mainly works with mixer, feeder, granulator, filling machine of capsule, pressing machine of tablet, etc. It can effectively avoid dust and cross-contamination, and fully meet the requirements of GMP in drug production.

It is also used for powder and granule materials transfer and storage in nutriceutical, animal remedy, food and chemical industry.

This bin is made of high quality austenitic stainless steel, and all inner corners and outer surfaces are circular arc transition, and there is no dead angle or residue. The inner surface is polished, the roughness reaches Ra≤0.2μm, the outer surface is brushed, and the roughness reaches Ra≤0.4μm. The cover is equipped with silicone rubber sealing device to ensure the sealing efficiency. The special butterfly valve with anti-misoperation device is designed to ensure the safety of production. There are special wheels to protect ground of clean area not be damaged, and no traces left.

It is used for storage and transfer powder and granule materials in nutriceutical, food, animal remedy, pesticides and chemical industry, and also can be equipped for mixer.

Special requirements for IBC Tank:

1. The IBC bin inlet and outlet and upstream and downstream equipment can be equipped with soft connection according to the requirements

2. 360 degree rotating cleaning ball can be set in the top of the warehouse according to the requirements, and there is no dead angle after cleaning.

3. The discharge port can be equipped with stainless steel rotary valve to meet the requirements of continuous quantitative discharge. IBC Tank mainly used for solid material transferring and charging ,can work with bin blender, pressing machine of tablets and filling machine of capsules, meanwhile, it is widely used in nutriceutical, animal remedy, chemical and food stuff industries .

When the Bin is pushed into the lifting arm, the lifting arm ascends or descends under the control of the electric gear motor, so as to complete material ascension, transportation and charging.

4.In order to transfer the pharmaceutical powder solid into processing easily ,so as usual the IBC bin will equipped a pneumatic or hydraulic lift system to transfer the IBC Bin

IBC Tank is made of high-quality stainless steel with inside and outside mirror polish and no dead angle, complying with GMP requirements.

IBC Tank is Sealed drug transportation prevents pollution in the process of transportation, dust floating as well as cross

contamination during production and transportation, in full compliance with GMP requirements.

1. The IBC bin inlet and outlet and upstream and downstream equipment can be equipped with soft connection according to the requirements

2. 360 degree rotating cleaning ball can be set in the top of the warehouse according to the requirements, and there is no dead angle after cleaning.

3. The discharge port can be equipped with stainless steel rotary valve to meet the requirements of continuous quantitative discharge. IBC Tank mainly used for solid material transferring and charging ,can work with bin blender, pressing machine of tablets and filling machine of capsules, meanwhile, it is widely used in nutriceutical, animal remedy, chemical and food stuff industries .

When the Bin is pushed into the lifting arm, the lifting arm ascends or descends under the control of the electric gear motor, so as to complete material ascension, transportation and charging.

4.In order to transfer the pharmaceutical powder solid into processing easily ,so as usual the IBC bin will equipped a pneumatic or hydraulic lift system to transfer the IBC Bin

IBC Tank is made of high-quality stainless steel with inside and outside mirror polish and no dead angle, complying with GMP requirements.

IBC Tank is Sealed drug transportation prevents pollution in the process of transportation, dust floating as well as cross

contamination during production and transportation, in full compliance with GMP requirements.

Details Images

Product Parameters

|

Item

|

Parameters

|

|

Model

|

LDF-1200

|

|

Volume

|

1200L

|

|

Thickness

|

300mm

|

|

Feed port

|

DN500

|

|

Discharge port

|

DN250

|

|

Material

|

SUS304/SUS316L

|

|

Size

|

1194*1194*1736mm

|

Hot Searches