- Product Details

- {{item.text}}

Quick Details

-

Positioning Accuracy (mm):

-

0.05 mm

-

Travel (X Axis)(mm):

-

1220 mm

-

Travel (Y Axis)(mm):

-

2800 mm

-

Repeatability (X/Y/Z) (mm):

-

0.05 mm

-

Spindle Motor Power(kW):

-

9

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KINGISO

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

3900*2300*2300mm

-

Power (kW):

-

9

-

Weight (KG):

-

2000

-

Processing range:

-

2880x1220x50mm

-

Spindle power:

-

9KW

-

Spindle speed:

-

24000r/min

-

Move quickly:

-

70m/min

-

Vacuum port:

-

150mm+100mm

-

After-sales Service Provided:

-

1 Year

-

Key words:

-

Cutting machines

-

Type:

-

KI-NC12

-

Country of origin:

-

China

-

Dimensions:

-

3900x2300x2300mm

Quick Details

-

Working Table Size(mm):

-

2800*1220*50

-

Machine Type:

-

Nesting CNC Router

-

Range of Spindle Speed(r.p.m):

-

24000 - 25000 rpm

-

Positioning Accuracy (mm):

-

0.05 mm

-

Travel (X Axis)(mm):

-

1220 mm

-

Travel (Y Axis)(mm):

-

2800 mm

-

Repeatability (X/Y/Z) (mm):

-

0.05 mm

-

Spindle Motor Power(kW):

-

9

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KINGISO

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

3900*2300*2300mm

-

Power (kW):

-

9

-

Weight (KG):

-

2000

-

Processing range:

-

2880x1220x50mm

-

Spindle power:

-

9KW

-

Spindle speed:

-

24000r/min

-

Move quickly:

-

70m/min

-

Vacuum port:

-

150mm+100mm

-

After-sales Service Provided:

-

1 Year

-

Key words:

-

Cutting machines

-

Type:

-

KI-NC12

-

Country of origin:

-

China

-

Dimensions:

-

3900x2300x2300mm

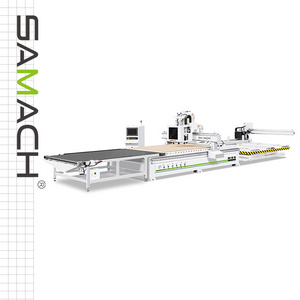

Products Description

|

Workable Size

|

2800*1220*50mm

|

|

Spindle power

|

9KW

|

|

Spindle speed

|

24000r/min

|

|

Traveling speed

|

70m/min

|

|

Working speed

|

18m/min

|

|

Vacuum port

|

φ150mm*1+φ100mm*1

|

|

Dimensions

|

3900*2300*2300mm

|

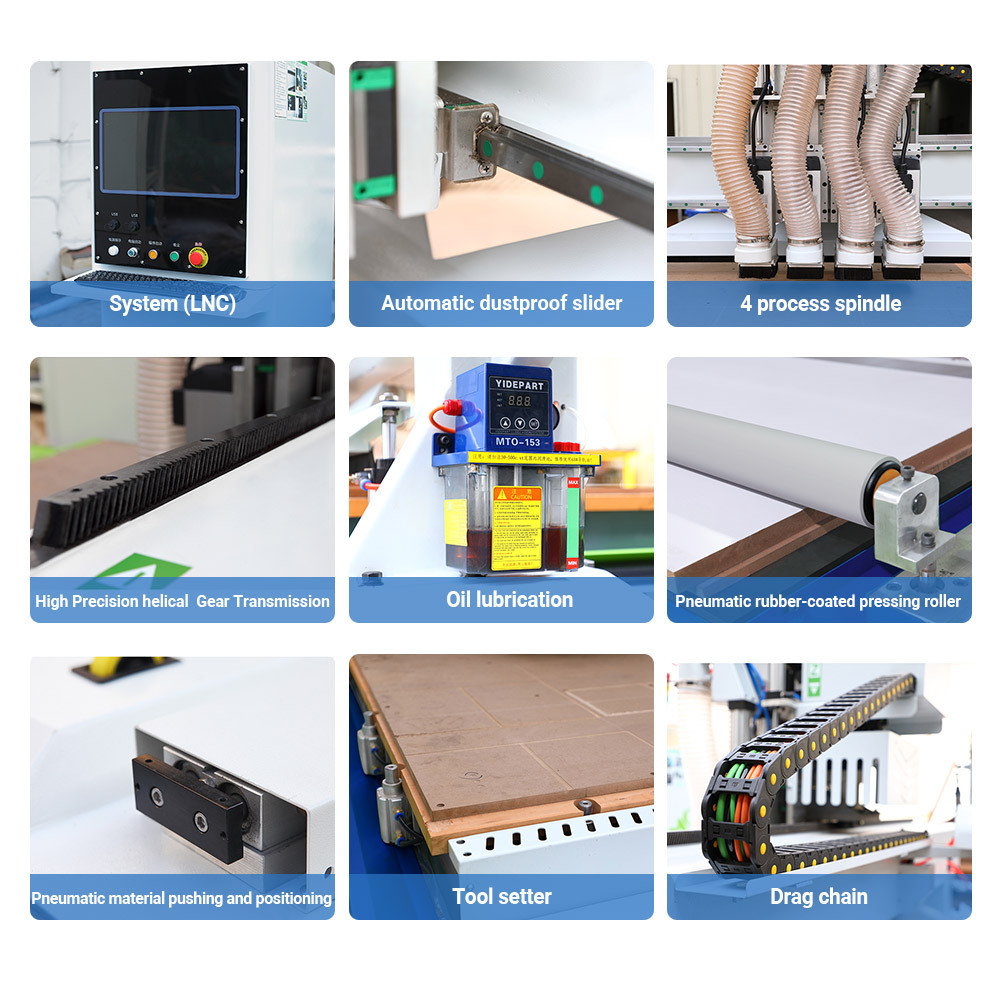

Application

KIN-NC4 CNC router cutting machine is a four-spindle linkage CNC

router

machine, which is a processing equipment that integrates blanking, drilling and milling. Accessories such as vacuum pump, automatic loading and unloading platform, pressing roller, and automatic grabbing can also be selected according to your needs.

Feature

1. Improve processing capacity and production efficiency.

2. Improve wood yield.

3. Improve product quality and processing precision.

4. Expand the technological range and increase the product variety.

2. Improve wood yield.

3. Improve product quality and processing precision.

4. Expand the technological range and increase the product variety.

Advantage

Greatly improve the processing capacity and production efficiency by shortening the auxiliary working time. In addition, it reduces the number of traditional machine tools, saves the number of operators and reduces the floor area of the workshop.

Greatly improve the processing capacity and production efficiency by shortening the auxiliary working time. In addition, it reduces the number of traditional machine tools, saves the number of operators and reduces the floor area of the workshop.

Finished Product

Related Products

24 Hours Online Service

Product Packaging

Hot Searches