- Product Details

- {{item.text}}

Quick Details

-

Panel Feed Speed(m/min):

-

23m/min

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zhongding

-

Weight (KG):

-

2800 kg

-

Panel Feed Speed(m/min):

-

23m/min

Product Description

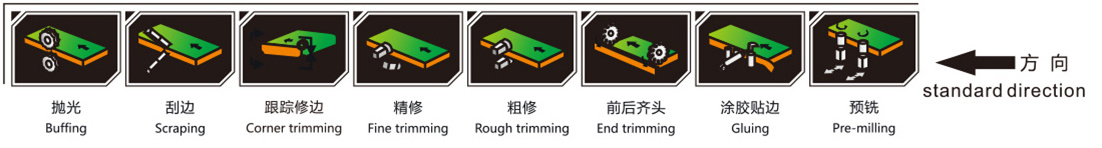

Pre-milling unit

Pre-milling equipment with double trimming blades works on the waved effect that is caused by sliding table saw, in order to get better edge banding effect.

End trimming

The end trimming system is used to cut off the cutting components of the front and rear edge tape. The end trimming device moves through precise linear guides, adopts automatic profiling and high-frequency electrode rapid cutting mechanisms to ensure that the cut surface is flat and smooth.

Sloting/grooving

The grooving device is used for direct grooving of side panels, bottom panels, etc., which reduces the process of panel saws and is more convenient and quick.

Gluing

The glue pot adopts imported special ball bearing and high hardness and super wear-resistant material glue box, the glue lifting shaft is patented design, CNC processing, to ensure the glue output, uniform daub, the glue surface hit 99.999%, the glue thickness can be controlled at will.

Rough and fine trimming

devices are used for trimming and processing the excess edge banding material on the upper and lower parts of the sheet edge banding. It adopts the structure of automatic profiling and high-frequency high-speed motor, etc. To ensure the smoothness of the upper and lower parts of the trimmed board edge.

Corner rounding unit

Corner rounding device aims to make the board corner more smooth and aesthetic.

Buffing unit

The buffing component polishes the edge and removes the sol residue on the workpiece. The polishing device uses a cotton polishing wheel to clean the processed plate. The edge-sealing end surface is smoother through polishing. The polishing component used for the upper surface of the workpiece is fixed on the workpiece.

Hot Searches