- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Kunshan Zhonggu

-

Model Number:

-

DIN7337

-

Product name:

-

Stainless/Steel blind rivets

-

Grade:

-

12.9/no Requirment

-

Surface treatment:

-

Electric Galvanized

-

Color:

-

Colorful

-

Packing:

-

Carton

-

Sample:

-

Avalible

Quick Details

-

Material:

-

Stainless steel, Steel

-

Finish:

-

zinc

-

Place of Origin:

-

Kunshan, China(mainland)

-

Brand Name:

-

Kunshan Zhonggu

-

Model Number:

-

DIN7337

-

Product name:

-

Stainless/Steel blind rivets

-

Grade:

-

12.9/no Requirment

-

Surface treatment:

-

Electric Galvanized

-

Color:

-

Colorful

-

Packing:

-

Carton

-

Sample:

-

Avalible

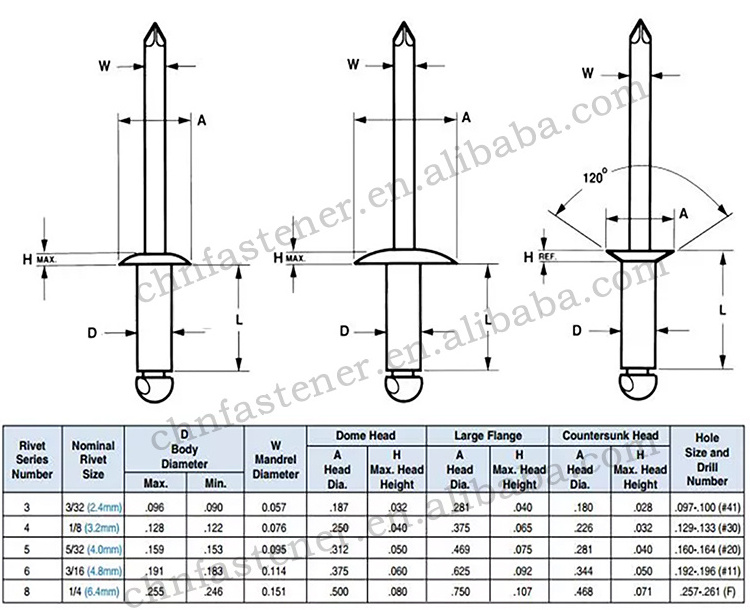

Aluminum Blind Rivet Zinc Plated Dome CSK Flat Head China Factory Break Manderl Blind Rivets

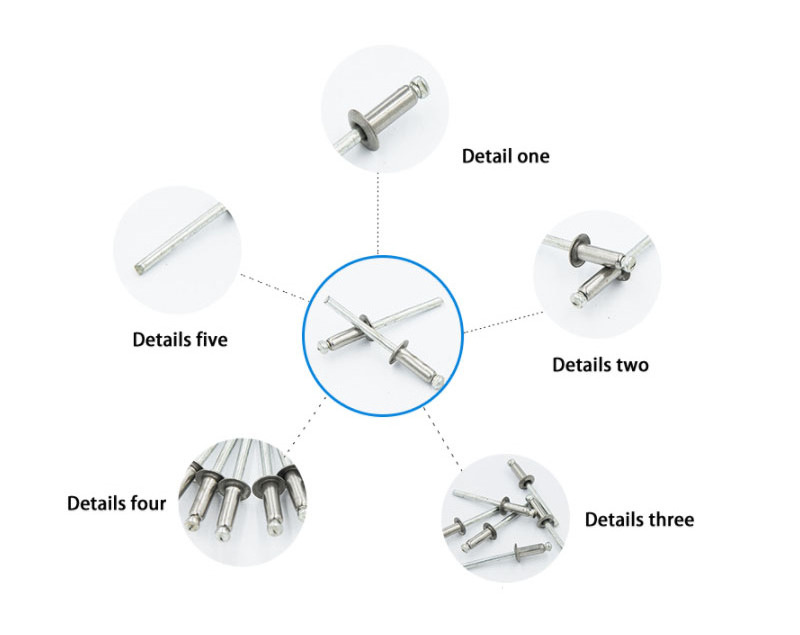

Blind rivet consists of a rivet body and a breaking mandrel. Provide fast, simple and strong fastening. Provide a variety of materials and finishing options.

| Material | Aluminum/Steel |

| Aluminum/ Stainless Steel | |

| Stainless Steel/ Stainless Steel | |

| Stainless Steel /Steel | |

| Copper /Steel | |

| Size and head type | Sizes: 3.2mm, 4.0mm,4.8mm, 6.4mm |

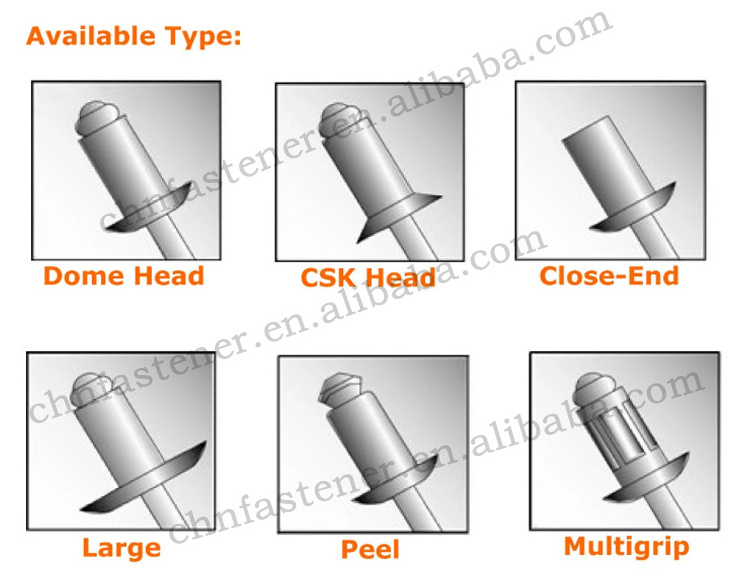

| Head forms: Dome Head ,CSK Head | |

| Applications | Automotive ,Cabinets and enclosures ,Heating and ventilating ,Telecommunications |

| Rive Types | A) Open Type Blind Rivet |

| 1. Aluminum/Steel Open Type 2. All Steel Open Type 3. All Stainless Steel Open Type 4. Stainless Steel/Steel Open Type | |

| 5. All Aluminum Open Type 6. Copper/Steel Open Type 7. Large Flange Open Type 8. Colored Open Type | |

| B) Peel Type Blind Rivet C). Sealed Type Blind Rivet D) Structual Rivet | |

| 1. Unigrip Type Rivet 2. Multi-grip Type Rivet 3. Cup Fix Rivet 4. Hem Fix Rivet 5. Grooved Type Blind Rivet |

We have Magnetic Powder Detector, Material Testing Machine, Metallographic Microscope, such testing instruments, guarantee product high quality and beautiful appearance.The quality control is strictly performed from buying raw materials in warehouse to different machining procession and to final packing.

First, we have our own High-precision Digital Machining center for mould making in special Mould Workshop, excellent mould make product beautiful appearance and its size accurately.

The second, we adopt blasting procession, removing Oxidation surface, make the surface to be bright and clean and uniform and beautiful.