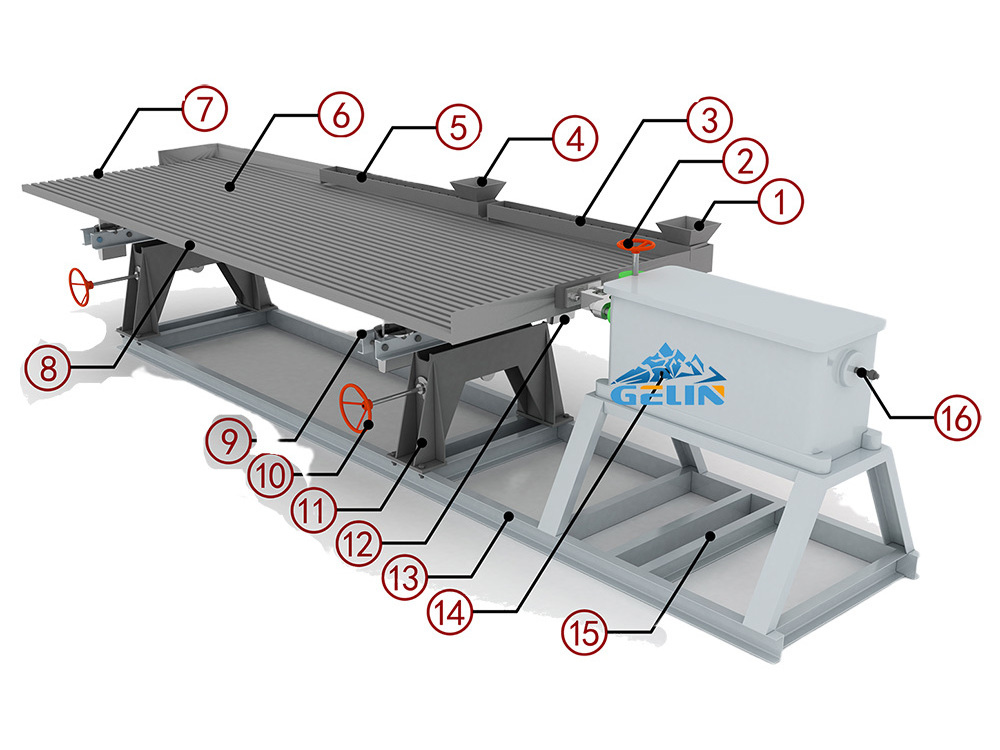

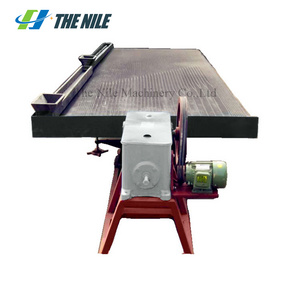

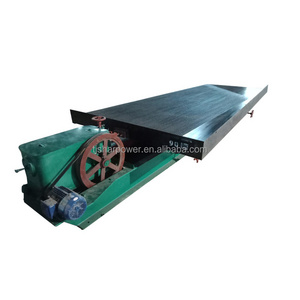

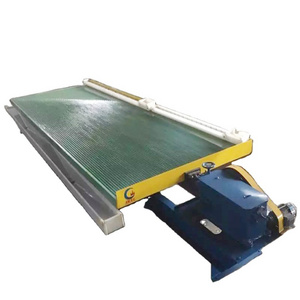

Different decks for different mineral sizes

features fine separation effect and high recovery:

46/60 riffles belong to coarse sand deck,used for separating 0.5--2mm;

88/120 riffles belong to fine sand deck, used for separating 0.074--0.5mm;

138 riffles belong to slurry deck,used for separating ≤0.074mm.

88/120 riffles belong to fine sand deck, used for separating 0.074--0.5mm;

138 riffles belong to slurry deck,used for separating ≤0.074mm.